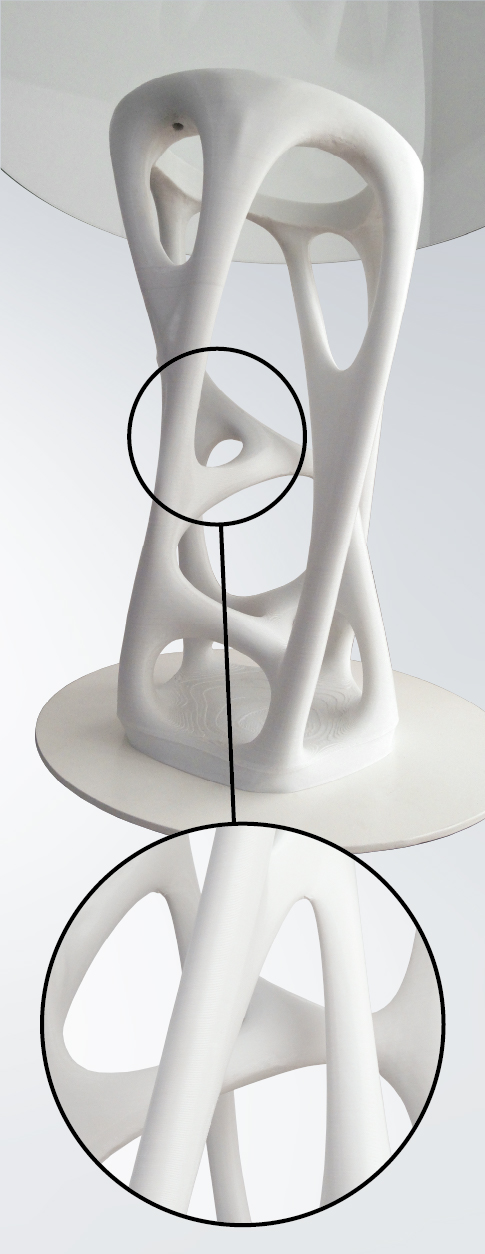

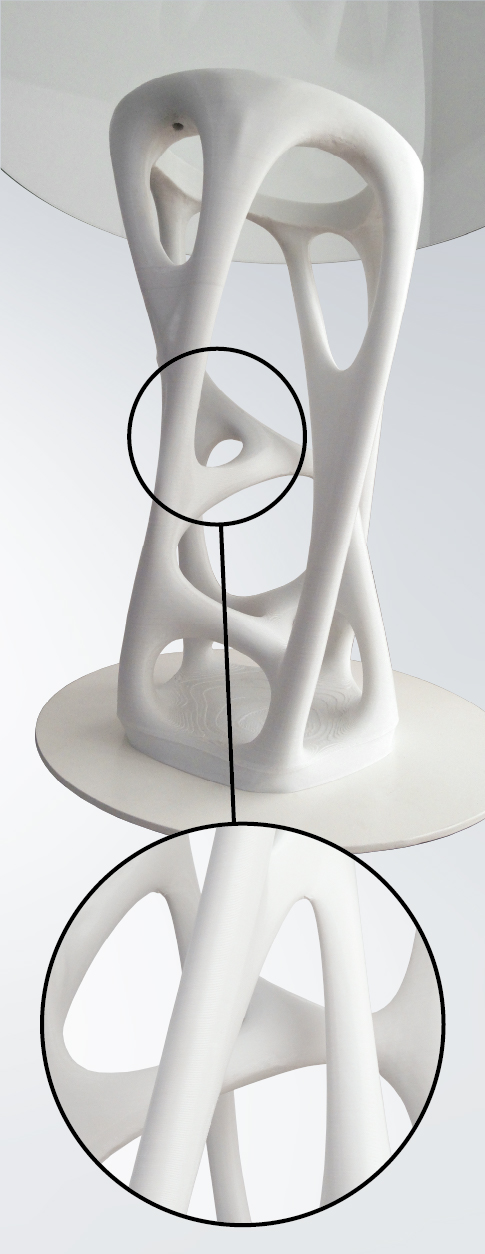

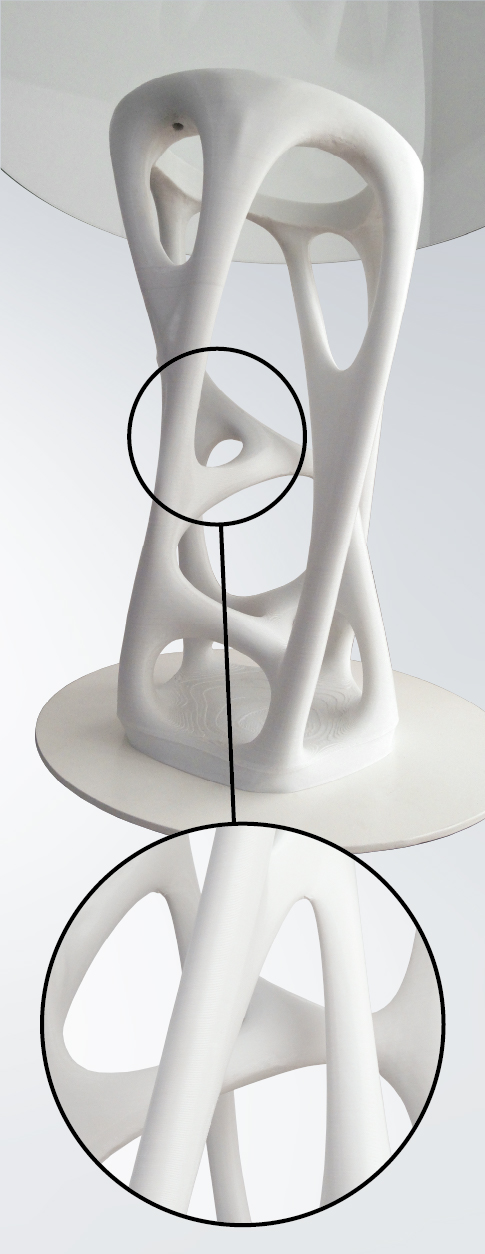

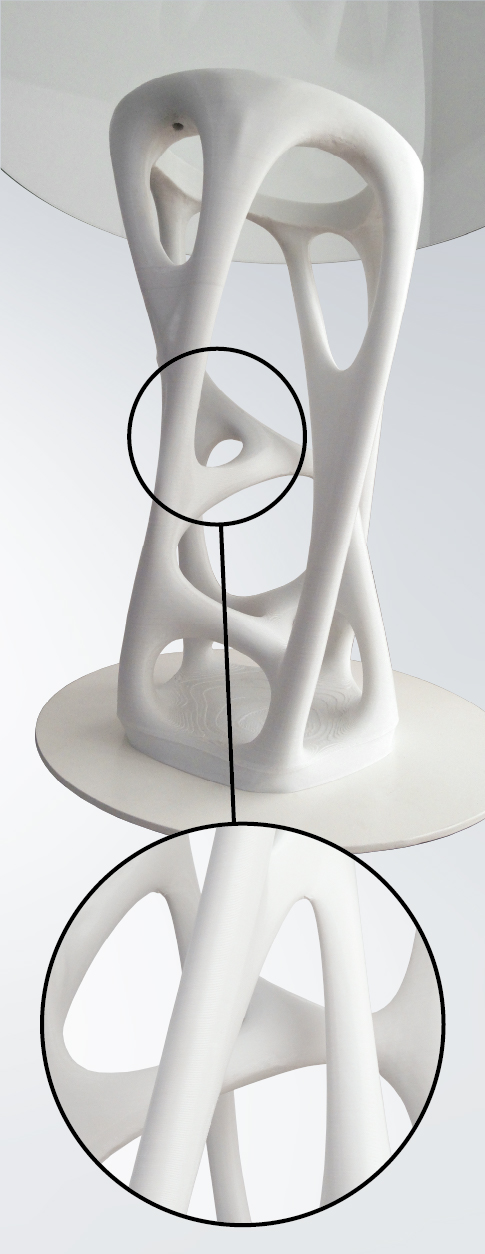

Case Study: Generative Design Table produced by 3D Printing

At REIMAN, we developed a table structure conceived through generative design and manufactured entirely by 3D printing. The project demonstrates how the combination of structural optimisation algorithms and additive manufacturing paves the way for innovative, functional and sustainable solutions.

By using EON PET,an engineering polymer processed by FDM (Fused Deposition Modelling), we were able to produce a robust and precise piece without the need for moulds or conventional processes. The material offers a remarkable balance of mechanical properties, tensile modulus up to 50 MPa, modulus of elasticity of 1.6 GPa and heat deflection temperature up to 68º C, ensuring durability even in applications subject to continuous stress.

The table's geometry was generated based on performance parameters, enabling us to leverage the potential of generative design to reduce waste and optimise material distribution, while also allowing us to achieve a highly innovative design. The structure ensures high strength, rapid execution and freedom of form, enabling the creation of complex designs that would be impractical using traditional methods.

Although applied in this case to a piece of furniture, the approach confirms the value of EON PET and additive manufacturing in sectors such as automotive, architecture, and industrial equipment, where there is a need for functional prototyping, customised structures, and technical components.

At REIMAN, we developed a table structure conceived through generative design and manufactured entirely by 3D printing. The project demonstrates how the combination of structural optimisation algorithms and additive manufacturing paves the way for innovative, functional and sustainable solutions.

By using EON PET, uan engineering polymer processed by FDM (Fused Deposition Modelling), we were able to produce a robust and precise piece without the need for moulds or conventional processes. The material offers a remarkable balance of mechanical properties, tensile modulus up to 50 MPa, modulus of elasticity of 1.6 GPa and heat deflection temperature up to 68º C, ensuring durability even in applications subject to continuous stress.

The table's geometry was generated based on performance parameters, enabling us to leverage the potential of generative design to reduce waste and optimise material distribution, while also allowing us to achieve a highly innovative design. The structure ensures high strength, rapid execution and freedom of form, enabling the creation of complex designs that would be impractical using traditional methods.

Although applied in this case to a piece of furniture, the approach confirms the value of EON PET and additive manufacturing in sectors such as automotive, architecture, and industrial equipment, where there is a need for functional prototyping, customised structures, and technical components.

At REIMAN, we developed a table structure conceived through generative design and manufactured entirely by 3D printing. The project demonstrates how the combination of structural optimisation algorithms and additive manufacturing paves the way for innovative, functional and sustainable solutions.

By using EON PET, an engineering polymer processed by FDM (Fused Deposition Modelling), we were able to produce a robust and precise piece without the need for moulds or conventional processes. The material offers a remarkable balance of mechanical properties, tensile modulus up to 50 MPa, modulus of elasticity of 1.6 GPa and heat deflection temperature up to 68º C, ensuring durability even in applications subject to continuous stress.

The table's geometry was generated based on performance parameters, enabling us to leverage the potential of generative design to reduce waste and optimise material distribution, while also allowing us to achieve a highly innovative design. The structure ensures high strength, rapid execution and freedom of form, enabling the creation of complex designs that would be impractical using traditional methods.

Although applied in this case to a piece of furniture, the approach confirms the value of EON PET and additive manufacturing in sectors such as automotive, architecture, and industrial equipment, where there is a need for functional prototyping, customised structures, and technical components.

At REIMAN, we developed a table structure conceived through generative design and manufactured entirely by 3D printing. The project demonstrates how the combination of structural optimisation algorithms and additive manufacturing paves the way for innovative, functional and sustainable solutions.

By using EON PET,an engineering polymer processed by FDM (Fused Deposition Modelling), we were able to produce a robust and precise piece without the need for moulds or conventional processes. The material offers a remarkable balance of mechanical properties, tensile modulus up to 50 MPa, modulus of elasticity of 1.6 GPa and heat deflection temperature up to 68º C, ensuring durability even in applications subject to continuous stress.

The table's geometry was generated based on performance parameters, enabling us to leverage the potential of generative design to reduce waste and optimise material distribution, while also allowing us to achieve a highly innovative design. The structure ensures high strength, rapid execution and freedom of form, enabling the creation of complex designs that would be impractical using traditional methods.

Although applied in this case to a piece of furniture, the approach confirms the value of EON PET and additive manufacturing in sectors such as automotive, architecture, and industrial equipment, where there is a need for functional prototyping, customised structures, and technical components.

This case study tangibly illustrates how REIMAN combines generative design and 3D printing to transform ideas into advanced solutions, combining innovation, efficiency, and mechanical reliability at the service of industry.