We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Threaded Inserts in Additive Manufacturing Parts

Threaded inserts are fasteners designed to be used in parts that are not strong enough to support a threaded connection directly. Additive manufacturing parts made of plastic can be produced with a thread included in the structure itself, however, in cases of frequent screwing, the part's thread will wear out, causing cross threading. In this case, designing a part with a purposeful area for installing threaded inserts will always be the safest option.

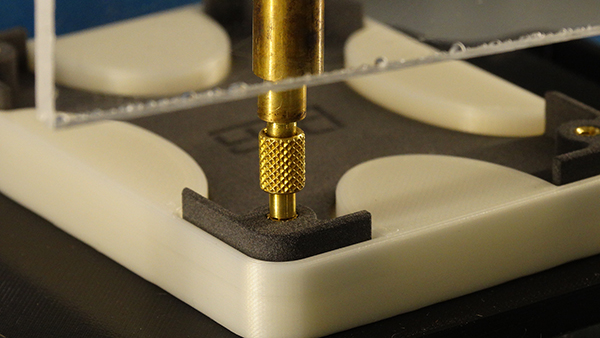

The method chosen for installing threaded inserts is called Heat Staking, which is a process based on heat and pressure. The process begins with the threaded insert being heated by induction and then being applied at high temperatures to the part's appropriate area for installing. When the insert is installed, the application time and pressure are controlled to ensure proper fitting without damaging the workpiece. Heat Staking is a fast process and ensures a greater operational consistency of the part, allowing it to have a longer lifespan.

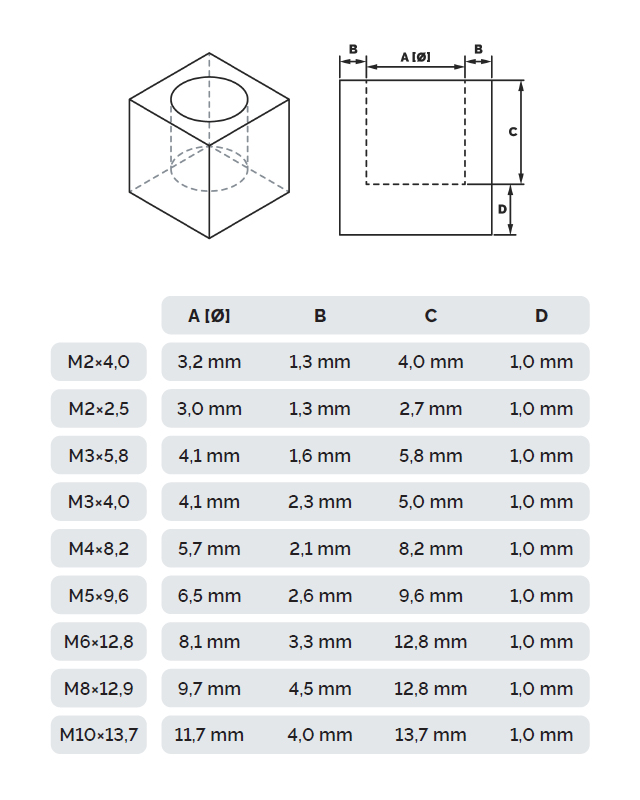

In order for the insert to be properly placed, some geometric rules that ensure correct coupling must be respected. These standards can be seen in the following table:

Get to know about RMN Additive additive manufacturing solutions. If you need a suitable solution for your project, contact us by phone or on our website at www.reiman.pt