We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Aluminum Structure for Machine with DBHAND System

REIMAN, in partnership with a client, developed and built an aluminum structure, designed to accommodate a high-precision machine, where the only access would be through a vertical sliding door.

This distinctive technical detail required an innovative approach from the technical teams involved. The project integrated aluminium profiles and accessories from Wolweiss, a DBHAND locking system, a pair of DZ2730 telescopic slides from Accuride, and four LV.A levelling feet from Elesa+Ganter.

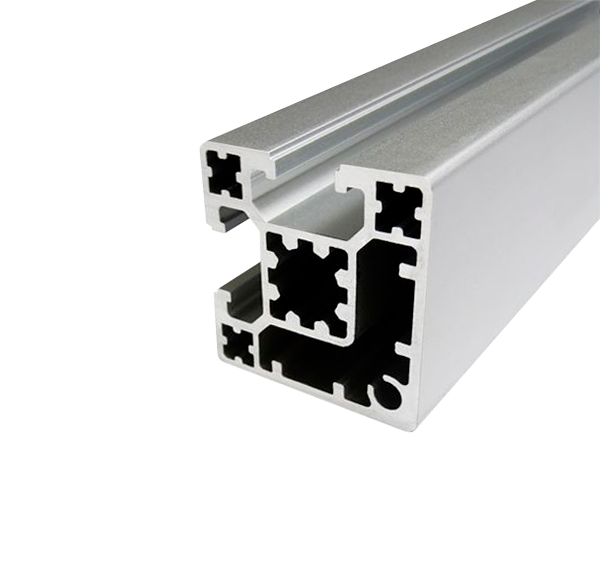

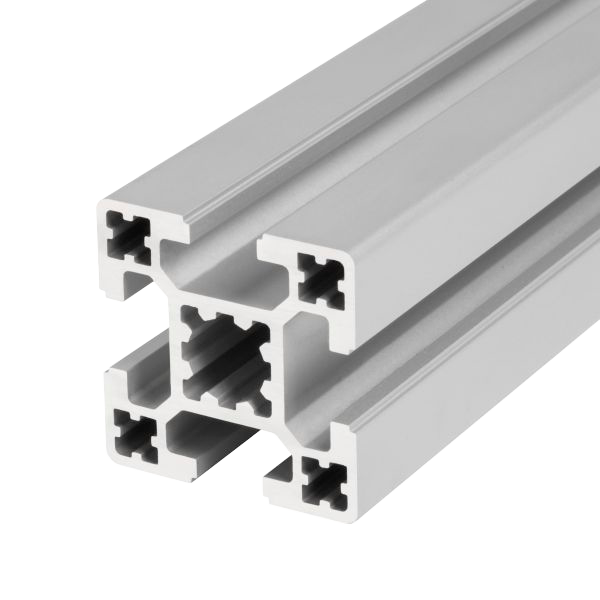

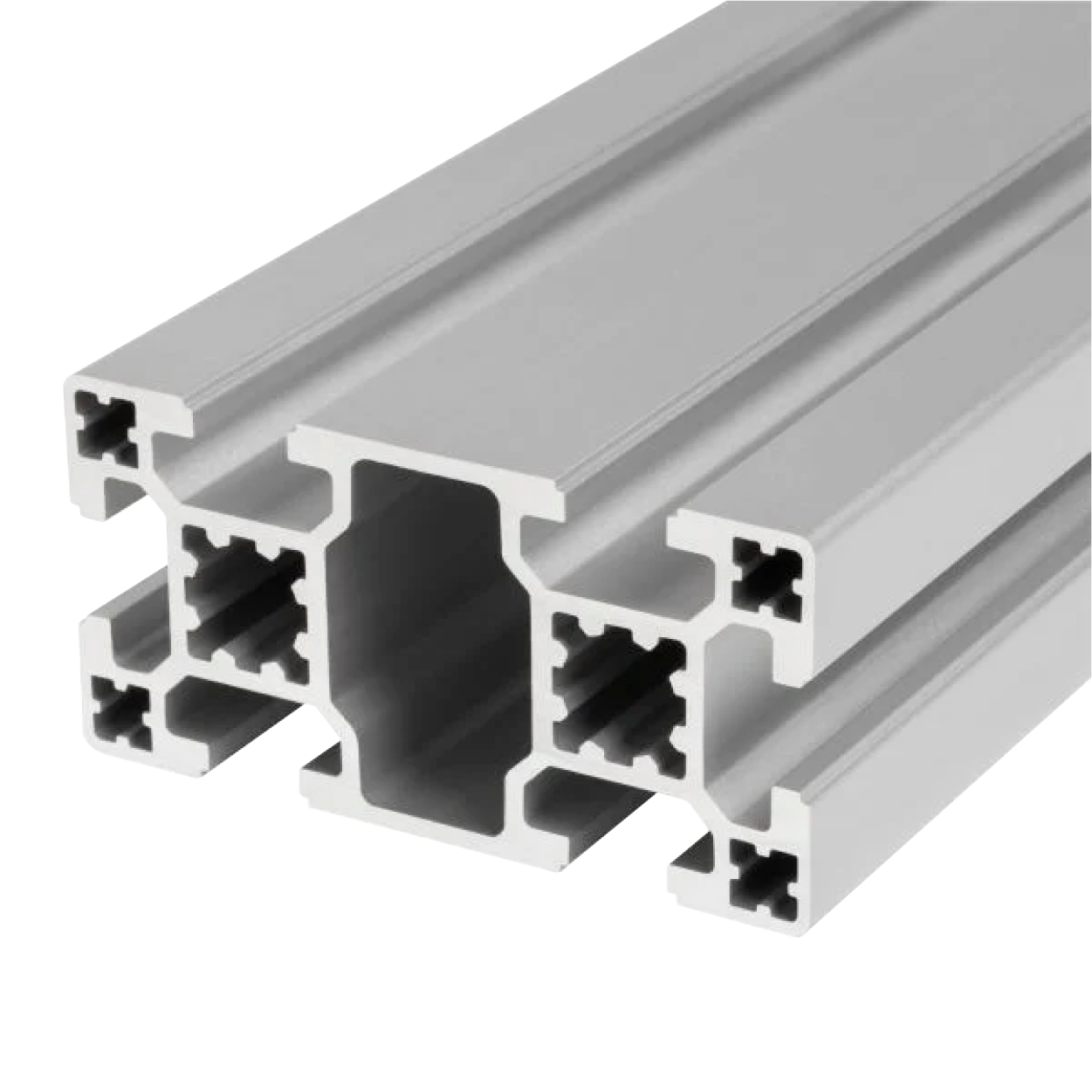

Aluminium Profiles and Accessories

The structure used a combination of different sizes and cross-section profiles from Wolweiss, which, together with a wide range of accessories, allowed for a modular and adjustable construction.

The aluminum profiles stand out for their lightness and high strength, which guarantees a solid and versatile base to support demanding industrial applications. The modularity of the profile made it possible to adapt the structure to the specific design of the machine.

Accessories

Accessories

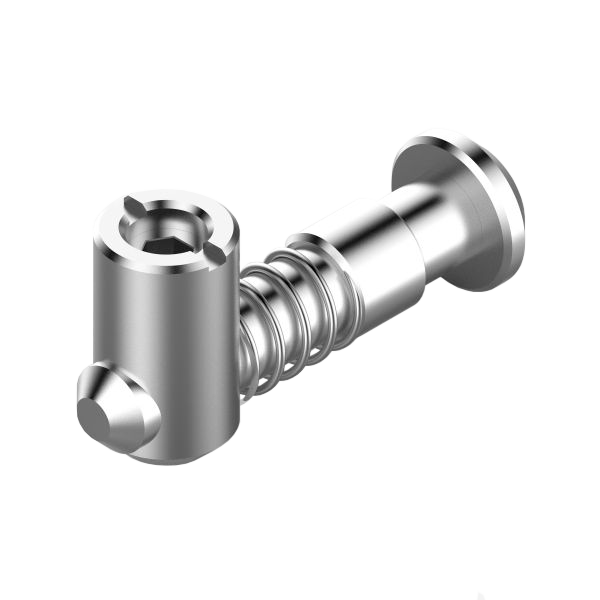

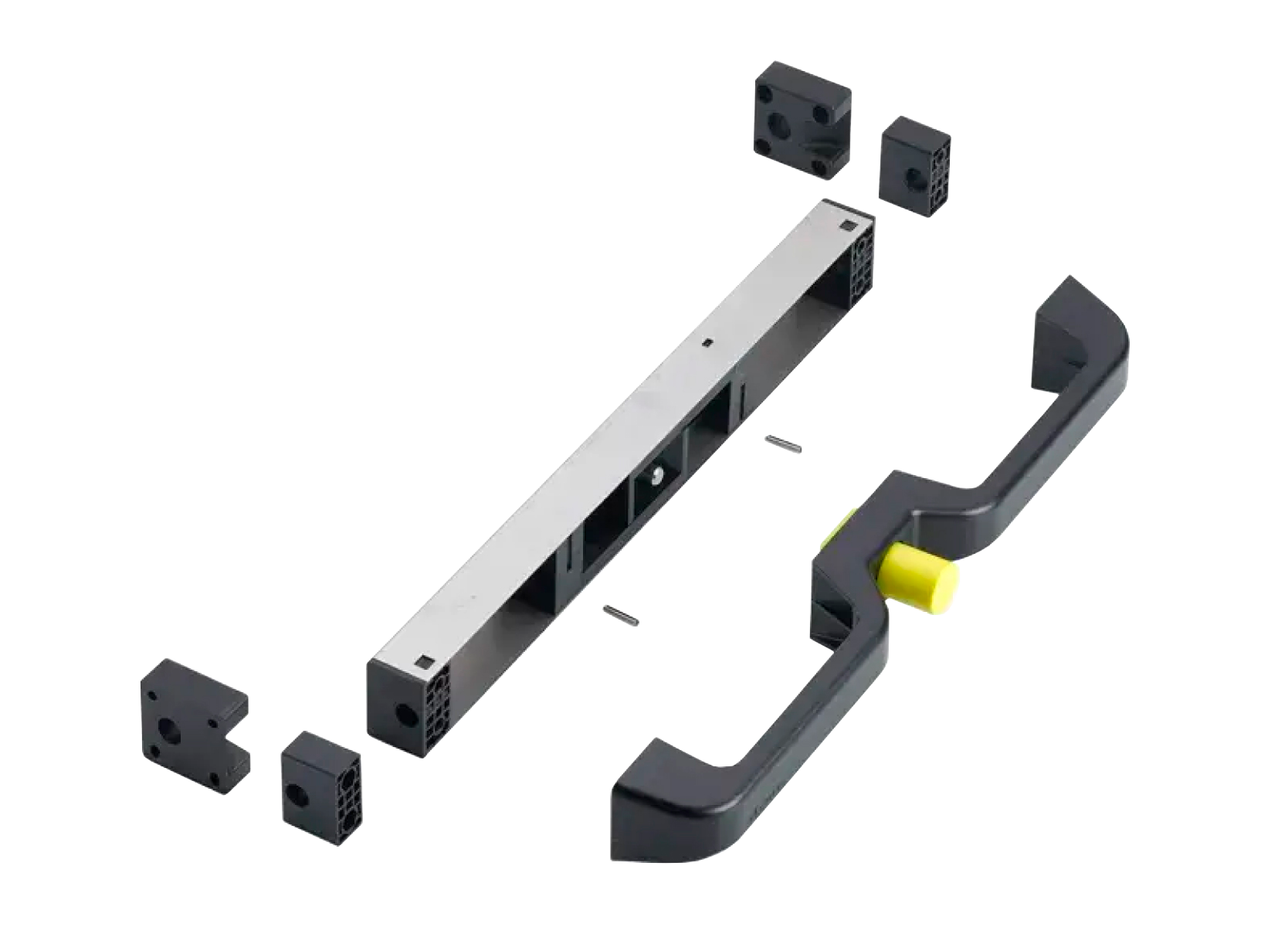

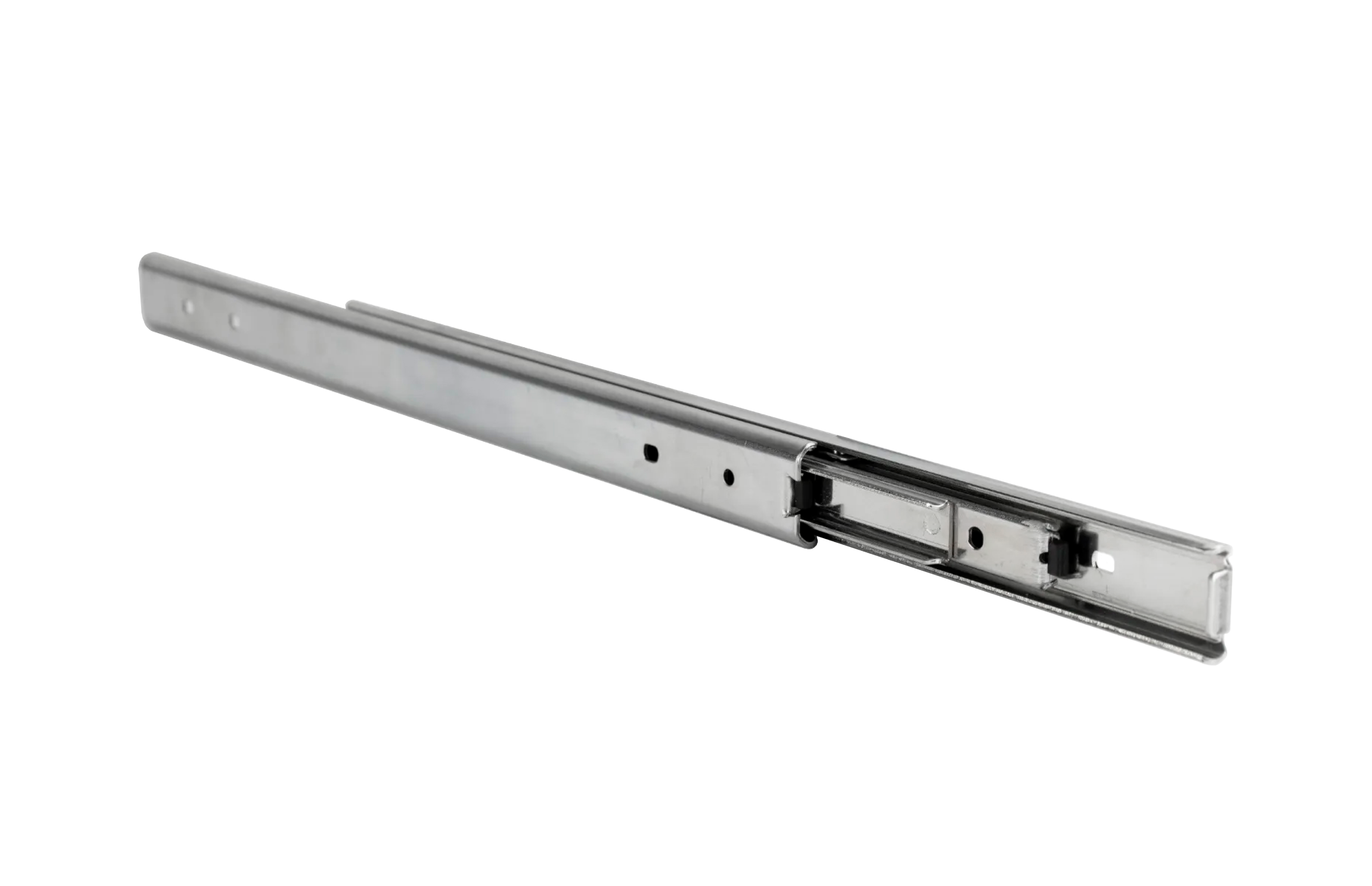

DBHAND + Telescopic Slides

Accuride's DBHAND has been incorporated to ensure secure control of access to the machine. This system has a centralized button that facilitates locking and unlocking and allows for different pressure settings, adapting to the operator's preferences. This system is corrosion-resistant.

Complementing the DBHAND, the DZ2730 telescopic slides provide smooth and safe movement for the vertical door. These slides support loads of up to 30 kg, have full extension and operate efficiently in temperatures ranging from -20 °C to +70 °C.

The integration of these elements has made it possible to optimize space, facilitate access to the equipment and guarantee greater durability and operational safety.

Leveling Feet

The Elesa+Ganter leveling feet were key to ensuring the structure's leveling and stability on uneven surfaces. With a fiberglass-reinforced technopolymer base and threaded galvanized steel stem, the feet provided excellent grip, reduced vibrations and improved the overall safety of the system.

The solution developed showed how the combination of high-quality components can effectively meet demanding industrial requirements. The integration of modular profiles, advanced locking systems and stabilization solutions resulted in a robust, efficient and safe structure.

This success story shows how innovation and the intelligent use of Wolweiss, Accuride and Elesa+Ganter products can offer customized, high-performance solutions to the most complex industrial challenges.