We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

How to choose the ideal linear guide for your project?

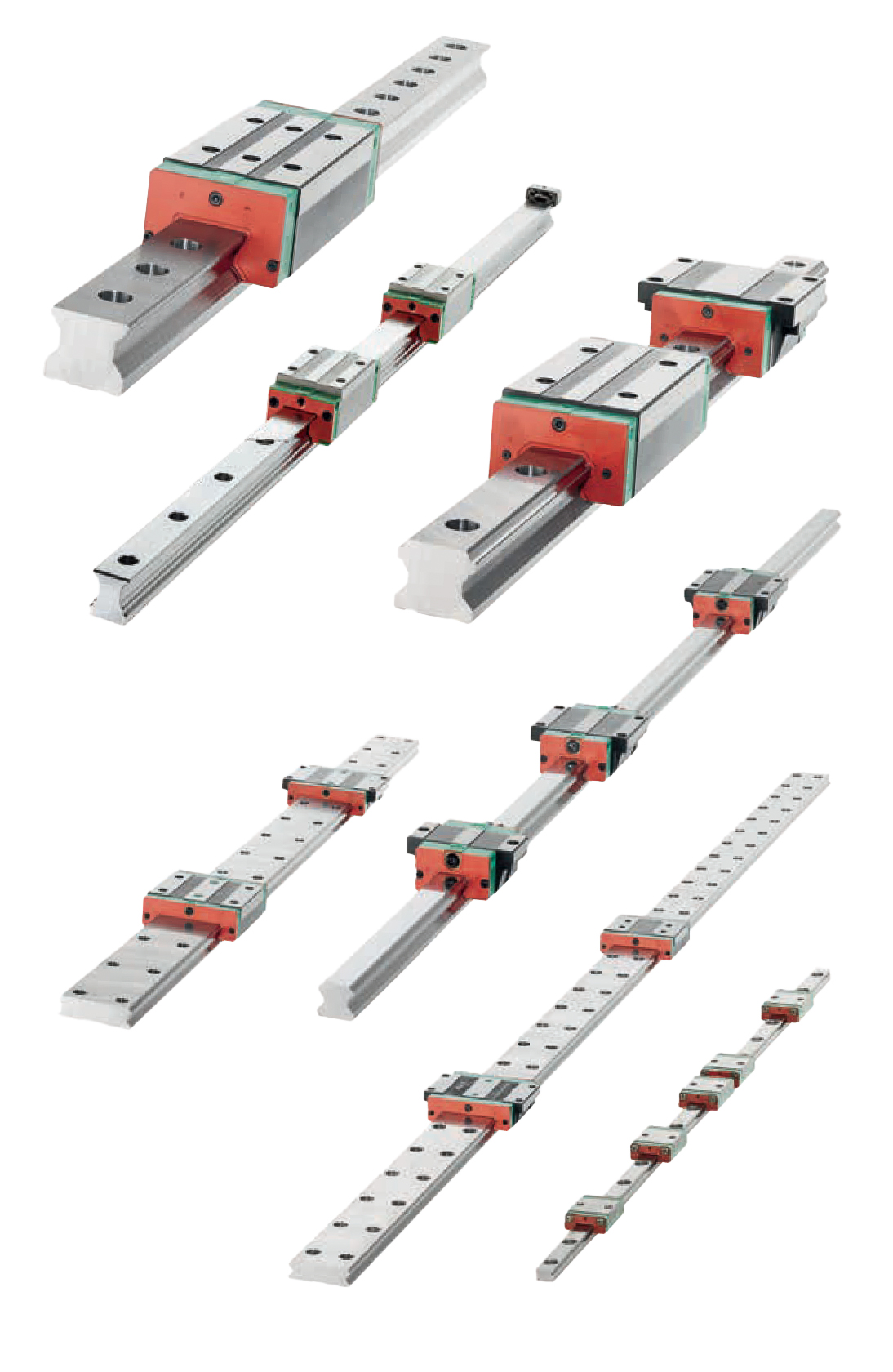

Linear guides are widely used in various industrial applications due to their high precision, reliability, durability, high load capacity, among others.

Reiman offers a variety of options to meet the specific needs of each application.

In order to choose the ideal option, it is important to follow some steps:

Determine the conditions in which the linear guide will be inserted:

- Machine or equipment;

- Maximum installation space;

- Desired accuracy;

- Required rigidity;

- Type of load;

- Distance, travel speed and acceleration;

- Frequency of use;

- Service life;

- Environmental conditions.

Select the desired series of linear guides, with some of the example provided, but adapting this selection to each project:

- Grinding machines, milling, drilling, lathes, machining centers, woodworking machines;

Miniature technology, semiconductor assembly, medical technology;

Automation technology, high-speed transport, semiconductor assembly, precision measurement equipment;

Machining centers, injection molding machines, high-rigidity machines and systems;

Single axes with Mx high-torque loads

Select the accuracy class:

- Classes C, H, P, SP, UP depending on the desired precision.

Calculate the size and number of blocks:

- Depending on empirical values;

- Take into account the type of load;

- When using them simultaneously and with the assistance of ball screw movement, it is advisable to ensure that the ball screw and linear guide sizes are similar; for example, a ball screw with a diameter of 32mm and a linear guide with a 35mm profile.

Determine the maximum load of the block:

- Calculate the maximum load per block, paying special attention to the load capacity of the guide+block combination, always ensuring static support stability is maintained.

Determine the preload:

- Depending on the rigidity requirements and the precision of the mounting surface.

Determine the rigidity:

- Use the rigidity table for each series to calculate guide deformation. Note that rigidity increases with higher preload and the use of wider and longer linear guides;

Calculate service life:

- Determine the necessary service life, considering both speed and movement frequency.

Choose the type of lubrification:

- Grease lubrification via grease nozzle;

- Oil lubrification via machine-integrated system.

Reiman also provides accessories to customize and adapt linear guides to meet your application's specific needs.

In addition to providing linear guides and their accessories, Reiman also offers a value-added service for customizing guide cutting.

For any questions, the specialized team at Reiman is available to assist in selecting the linear guide that offers the best price and quality combination for your project.