We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

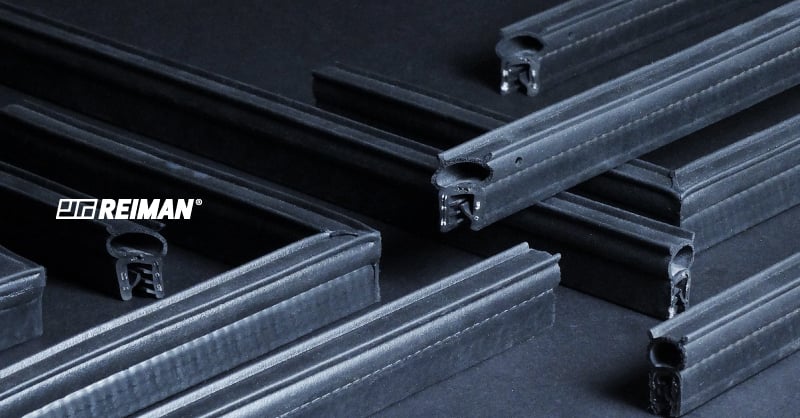

The Versatility of EPDM Gaskets

EPDM is an elastomer used in various industrial sectors due to the benefits this material provides for protecting equipment. EPDM gaskets, notable for their durability, flexibility and resistance, are an essential solution for applications that require reliable, long-lasting performance in a variety of environmental conditions.

EPDM synthetic rubber stands out for its resistance to UV rays and wear, while also demonstrating excellent performance at temperatures ranging from -35°C to 130°C. As well as having flame-retardant properties, this material is formulated to resist chemical agents.

Applications of EPDM seals in various industrial sectors

In the switch cabinet construction industry, EPDM is often used to protect sensitive electrical components from moisture, dust and temperature changes. Its material properties ensure that electrical enclosures remain well sealed, reducing the risk of corrosion and electrical failures.

In the transport sector, vehicles are constantly exposed to different levels of temperature, sunlight and various chemicals, and EPDM can withstand these factors without losing its integrity. This helps to improve vehicle performance and safety, particularly in critical areas such as door and window seals, thus ensuring that they remain insulated throughout the life of each vehicle.

In the HVAC industry, EPDM is significantly valued for its thermal insulation and moisture resistance capabilities. Used in components such as pipe and duct insulation, EPDM material ensures that HVAC systems operate efficiently, with minimal heat loss or condensation problems. It also retains its flexibility over time, even when subjected to extreme temperature variations, making it a reliable material for long-term use in HVAC systems.

In short, EPDM seals are a viable and safe bet for a wide range of industries. Its excellent material properties make it an ideal choice for applications where flexibility, durability and thermal stability are essential, consistently proving its worth as a robust and economical synthetic rubber.