We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

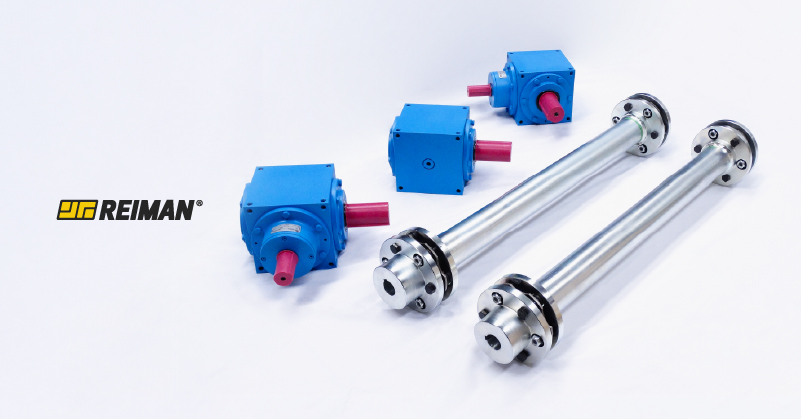

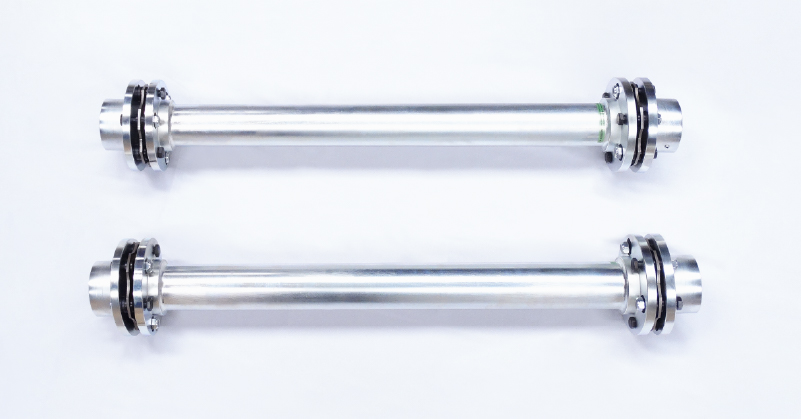

Torsionally Rigid Coupling with Spacer – Precision, Robustness and Technical Reliability

In an industrial environment where mechanical reliability and fatigue resistance are critical, this coupling stands out due to its special steel construction and stainless steel disc packs, delivering a robust and maintenance-free performance.

This coupling is designed to connect two separated shafts via a custom central spacer, tailored to the specific requirements of each application.

The stainless steel discs, made from AISI 301 or reinforced AISI 304-C, ensure high mechanical strength while maintaining the flexibility required to accommodate angular misalignments and reduce shaft stresses.

Technical Highlights:

- Fully machined steel body with anti-corrosion surface treatment.

- Disc pack in AISI 301 stainless steel (or reinforced AISI 304-C), connected by steel bushings and secured with grade 10.9 bolts and self-locking nuts.

- Maintenance-free operation, even in demanding environments.

- Optional dynamic balancing (Q=2.5) according to DIN ISO 1940-1:2003 to minimise vibrations and extend system lifespan.

- Optional welded spacer version available for increased torsional rigidity.

Recommended Applications:

Ideal for industrial drives operating at high rotational speeds, elevated temperatures (>150 °C), and where backlash elimination and predictive maintenance are critical priorities.

Combining precision engineering, careful material selection, and adaptability to each project, these couplings are the right solution for those seeking high technical reliability and proven mechanical durability.