What are Screw Jacks?

Screw Jacks are transmission components whose function is to convert circular motion into linear motion. This is a mechanism that can be used to move weights with a minimal applied force, by means of a spindle driving the carried weight. Screw jacks' different applications approach carrying weight by pushing or pulling, lifting or lowering, locking or unlocking, sliding, rolling, tilting and tensioning.

Whatever type of screw jack is added, the carrying capacities can be used in applications for small weights from just a few kilograms up to hundreds of tons.

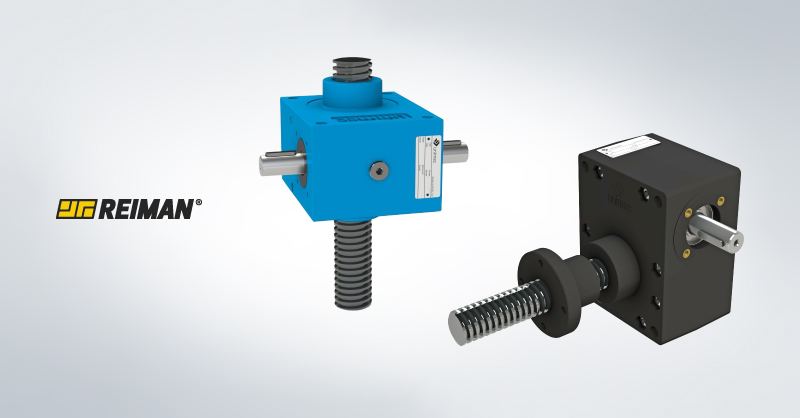

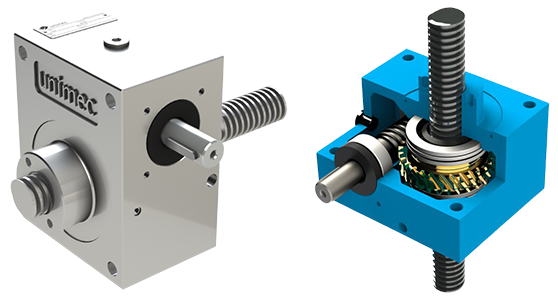

Trapezoidal Screw Jacks

Trapezoidal spindle screw jacks are components that act directly on the threaded shaft accommodated by the worm wheel. These are represented in two models, each model having a specific operation method:

TP Screw Jack: This screw jack method consists in translating a fixed trapezoidal spindle. The spindle, whether fixed to a surface or a platform, undergoes a translational movement through the screw jack's worm wheel, adjusting the positioning of the screw jack to the specified area of the thread.

TPR Screw Jack: This screw jack method is based on the spindle's rotary movement. This spindle, fixed to the screw jack's worm wheel, carries a threaded nut, which moves linearly along the spindle. The spindle's rotation causes the female to move along the shaft, following the weight applied to it.

Additional Functions in Trapezoidal Screw Jacks

There are screw jacks equipped with additional functions such as safety nuts, anti-rotation systems, and linear braking elements, ensuring that a secondary safety measure is always active:

- In TP screw jacks, in order for the spindle to stay at the same angle, the application of anti-rotation system accessories is recommended, depending on the specific application.

- TP screw jacks have a safety nut system implemented on the worm wheels. When the worm wheel begins to yield to excessive weight, the safety nut engages and protects the worm wheel by shielding it from the weight, decreasing in size with wear and requiring replacement when the support no longer supports the heavy load.

- TPR screw jacks can be equipped with safety nuts that contain secondary nuts allowing wear control and redundancy if the load-carrying nut gives in. In cases of greater care and supervision, sensors can be installed to detect failure/maximal wear reached.

- In both methods, screw jacks have a self-locking system because their spindle has a trapezoidal shape combined with a worm gear, resulting in static self-locking of the load when the drive is removed.

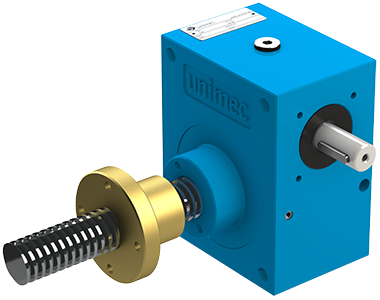

Ball Screw Jacks

Ball screw jacks are systems where the spindle's drive is provided by the ball screw implemented in the worm wheel, offering higher efficiency between useful input and output, as well as allowing higher rotation speeds and, due to low friction, greater durability.

However, a ball screw jack does not have a self-locking system, and due to its more precise components, the initial cost is higher. The resulting improved efficiency implies that this can be compensated by smaller transmission components and a significant reduction in the power required for its drive.

Energy Management

Screw jacks typically work in high load applications. The competing technology with high loads tends to be hydraulics; however, hydraulics are less energy efficient than the electromechanical solution provided by screw Jacks. Hydraulic systems waste energy as fluid circulates at constant pressure, regardless of the amount of work required to be performed by hydraulic positioning. A hydraulic cylinder requires constant pressure to maintain its position when holding a load in place. In contrast, an electric motor used to power a Screw Jack uses energy only when driving the load to the desired position

Application Examples

Screw jacks are used in a wide spectrum of applications reaching all market sectors, including steel equipment, water processing, pharmaceuticals, medical and laboratory equipment, packaging equipment, nuclear and aerospace, and general mechanical handling. In addition, screw jacks are increasingly used as alternatives to conventional pneumatic and hydraulic systems.

Get to know our screw jack solutions. If you need a suitable solution for your project, contact us by phone or on our website at www.reiman.pt