What is a gearbox and what is it for?

A gearbox is used to reduce the motor output speed. There is a gear train between the motor and the gearbox that allows the output shaft to rotate more slowly resulting in a speed reduction. In general, all gearboxes are made up of:

- 2 axes (input and output)

- Bearings

- Gears

- Frame (aluminium or cast iron)

In addition to this, they also have a number of common features, namely high performance, low noise level and versatility.

Main types of gearboxes:

1. Planetary Gearboxes

Planetary gearboxes are characterized by their high level of precision and performance, as well as by their resistance. The planetary gearboxes have a low inertia with respect to their rotating components.

The use of this type of gearboxes is recommended for applications where there are strong changes in acceleration and deceleration. As they allow a very high transmission ratio, they are also often used in public works and agriculture.

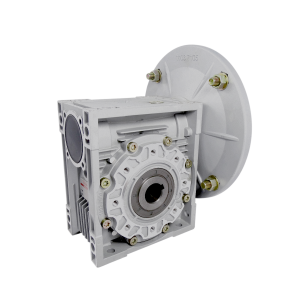

Worm gearboxes are usually applied in situations that require a high level of demultiplication. These gearboxes constitute a high-quality modular solution, which has the power to transform power into motion (speed and torque) for the most varied applications. As this is a gearbox with irreversible gears, it ensures higher safety. Its anti-vibration system makes it less noisy than the other ranges. As mentioned above, these reducers are applicable to several solutions, however, the most common are load handling equipment.

3. Helical Gearboxes

Helical gearboxes have a particularly high price. They are very efficient gearboxes with helical gear. This gearbox is the ideal solution when you need to work at a particular speed and torque. Widely used for different industrial applications, it guarantees high performance when it comes to speed reduction.

4. Bevel Gearboxes

These gearboxes are characterized by their cone-shaped gear that allows changing the rotation system of the machines. Their main advantage is the efficiency of the gears which can have up to 98% effectiveness and therefore have a low level of power loss. Like the worm gearboxes, these gearboxes are used for large power transmissions due to their compact size and robustness. The main "defect" of bevel gearboxes is that they require a lot of maintenance. They are usually applied on mobile machines.

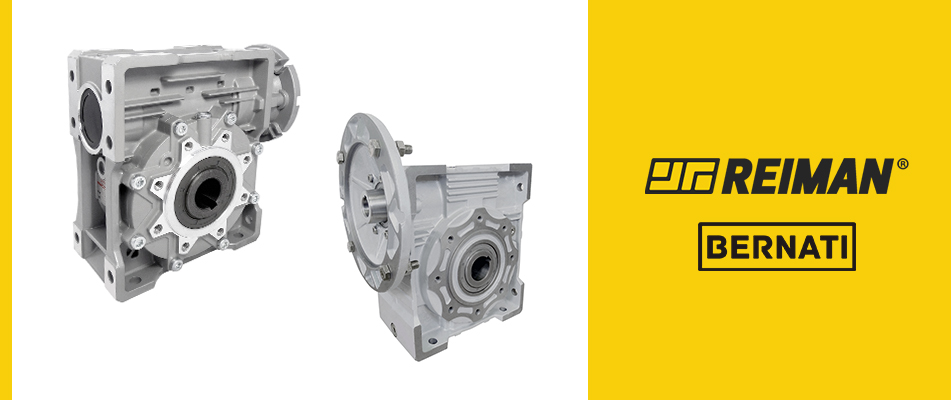

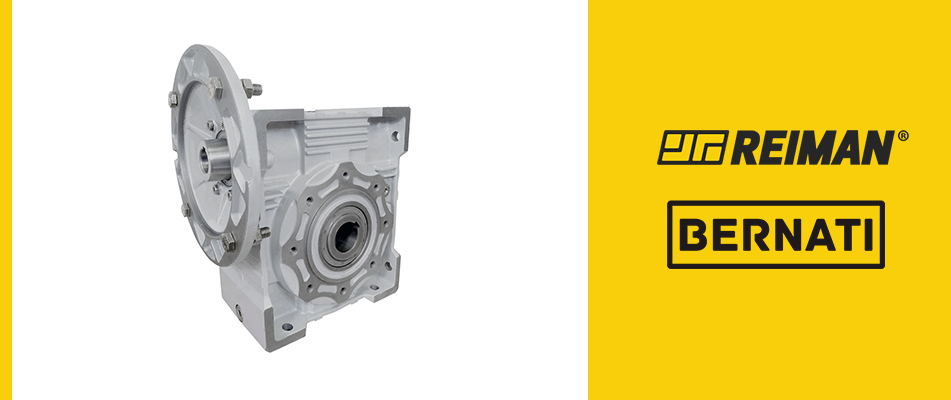

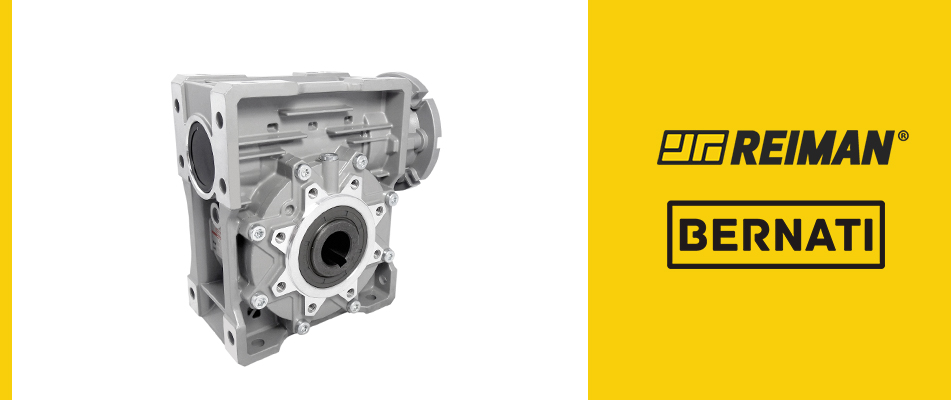

BV Worm Gearbox - Bernati

The BERNATI range of gearboxes for electric motors is composed of two series with multiple configurations that allow simple integration in equipment design.