Why do technical errors start before the installation phase? | REIMAN

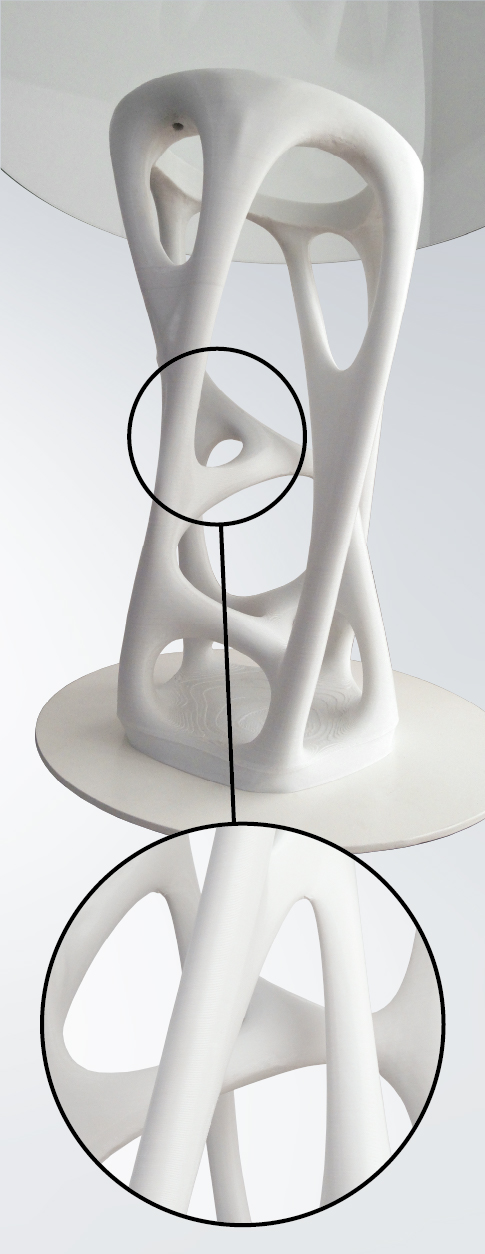

At REIMAN, we developed a table structure conceived through generative design and manufactured entirely by 3D printing. The project demonstrates how the combination of structural optimisation algorithms and additive manufacturing paves the way for innovative, functional and sustainable solutions.

By using EON PET, uan engineering polymer processed by FDM (Fused Deposition Modelling), we were able to produce a robust and precise piece without the need for moulds or conventional processes. The material offers a remarkable balance of mechanical properties, tensile modulus up to 50 MPa, modulus of elasticity of 1.6 GPa and heat deflection temperature up to 68º C, ensuring durability even in applications subject to continuous stress.

The table's geometry was generated based on performance parameters, enabling us to leverage the potential of generative design to reduce waste and optimise material distribution, while also allowing us to achieve a highly innovative design. The structure ensures high strength, rapid execution and freedom of form, enabling the creation of complex designs that would be impractical using traditional methods.

Although applied in this case to a piece of furniture, the approach confirms the value of EON PET and additive manufacturing in sectors such as automotive, architecture, and industrial equipment, where there is a need for functional prototyping, customised structures, and technical components.

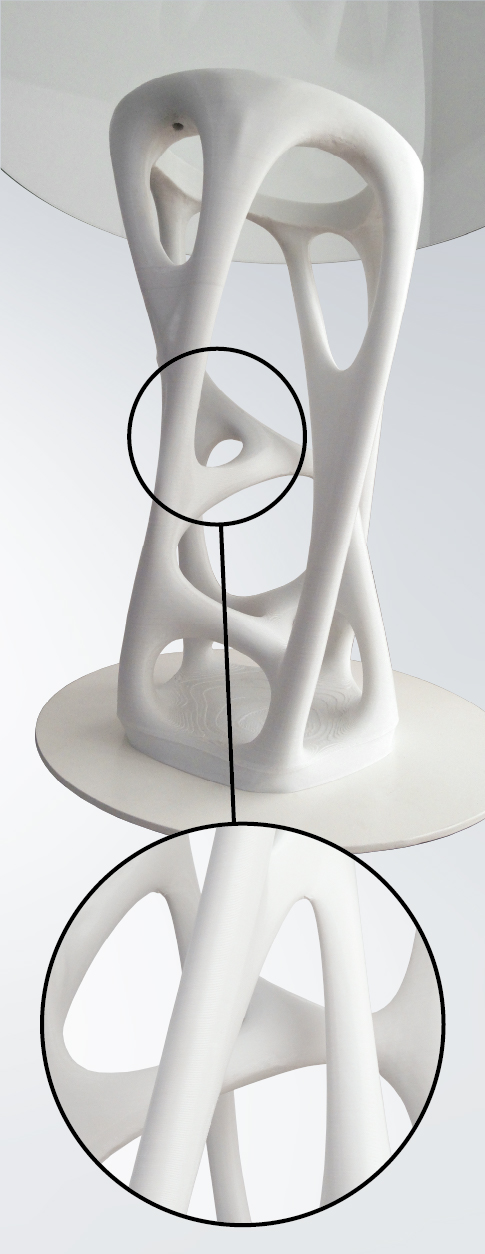

At REIMAN, we developed a table structure conceived through generative design and manufactured entirely by 3D printing. The project demonstrates how the combination of structural optimisation algorithms and additive manufacturing paves the way for innovative, functional and sustainable solutions.

By using EON PET, an engineering polymer processed by FDM (Fused Deposition Modelling), we were able to produce a robust and precise piece without the need for moulds or conventional processes. The material offers a remarkable balance of mechanical properties, tensile modulus up to 50 MPa, modulus of elasticity of 1.6 GPa and heat deflection temperature up to 68º C, ensuring durability even in applications subject to continuous stress.

The table's geometry was generated based on performance parameters, enabling us to leverage the potential of generative design to reduce waste and optimise material distribution, while also allowing us to achieve a highly innovative design. The structure ensures high strength, rapid execution and freedom of form, enabling the creation of complex designs that would be impractical using traditional methods.

Although applied in this case to a piece of furniture, the approach confirms the value of EON PET and additive manufacturing in sectors such as automotive, architecture, and industrial equipment, where there is a need for functional prototyping, customised structures, and technical components.

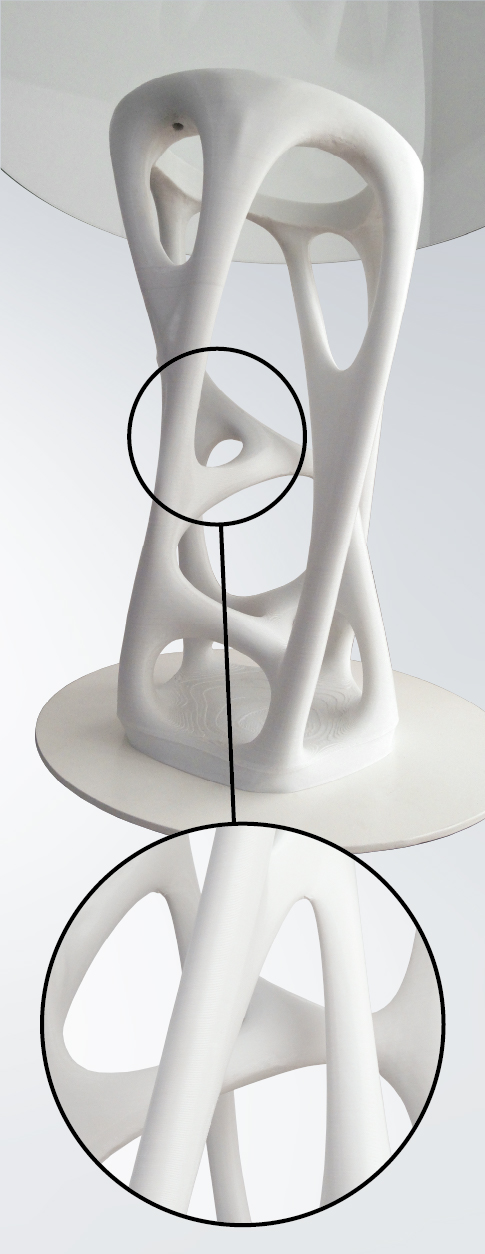

At REIMAN, we developed a table structure conceived through generative design and manufactured entirely by 3D printing. The project demonstrates how the combination of structural optimisation algorithms and additive manufacturing paves the way for innovative, functional and sustainable solutions.

By using EON PET,an engineering polymer processed by FDM (Fused Deposition Modelling), we were able to produce a robust and precise piece without the need for moulds or conventional processes. The material offers a remarkable balance of mechanical properties, tensile modulus up to 50 MPa, modulus of elasticity of 1.6 GPa and heat deflection temperature up to 68º C, ensuring durability even in applications subject to continuous stress.

The table's geometry was generated based on performance parameters, enabling us to leverage the potential of generative design to reduce waste and optimise material distribution, while also allowing us to achieve a highly innovative design. The structure ensures high strength, rapid execution and freedom of form, enabling the creation of complex designs that would be impractical using traditional methods.

Although applied in this case to a piece of furniture, the approach confirms the value of EON PET and additive manufacturing in sectors such as automotive, architecture, and industrial equipment, where there is a need for functional prototyping, customised structures, and technical components.

Why do technical erros start before the installation phase? | REIMAN

In many technical projectsm problems do not arise during installation or immediate use. They appear much earlier - during the design and decision-making phase.

It is at this stage that key choices are made, determining durability, reliability, and costs throughout the project´s lifecycle.

Decisions made during the design phase

During the design phase, it is common to select solutions based on habits, previously used references, or constraints related to budget and timelines. However, technical decisions made without thorough analysis can compromise system performance from the start.

The choice of inappropriate components, materials, or specifications creates weaknesses that only become visible later - when corrections are already complex and costly.

Lack of analysis of real operating conditions

One of the most frequent mistakes is failing to consider real operating conditions.

Factors such as load, frequency of use, environment, tolerances, or functional requirements are not always properly assessed during the early stages. When real-world conditions are not integrated into technical decisions, a solution may work in the short term but fail prematurely over time.

Impact on durability and costs

Poorly grounded technical choices have direct consequences:

- accelerated component wear,

- increased maintenance,

- unplanned downtime,

- and additional costs throughout the projet lifecyle.

Conversely, well-analyzed technical decisions made during the design phase reduces risks, increases durability, and optimizes costs in the medium and long term

Conclusion

Avoiding technical errors does not depend solely on proper installation, but above all on making the right decisions before that phase.

Analyzing the real application context and selecting appropriate solutions from the start is the foundation of more reliable and sustainable projects.

When technical requirements are high, anticipating issues is always more efficient than correcting them later.