We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Surface Treatment on Additive Manufacturing Parts

It's common to see that 3D printed parts, once completed, reveal a type of texture based on the technology in which they were produced. Depending on the function, it is important that the part's surface has certain characteristics that eliminate the risk of compromising its functionality or that of the assembly it is part of.

While various additive manufacturing technologies specialize in building a part with the accuracy and demands associated with quality requirements, surface treatment specializes in enhancing the part of prominent textures or retained waste, and RMN Additive offers the following surface treatment services for additive manufacturing parts:

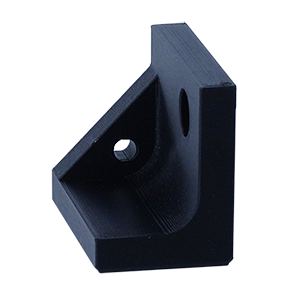

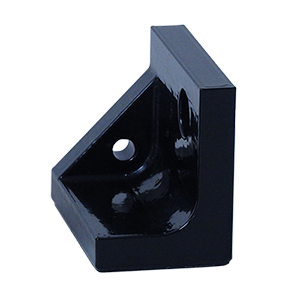

Polishing

Polishing is a machining process applied through vibratory finishing equipment. Proprietary recipes of media, paste and liquid are applied to achieve a delicate high-quality finish on AM parts.

The surface of the printed product becomes shinier and more compact, and its corners and edges become rounder due to the polishing process. Basically, the surface no longer has the characteristics it had at the end of its production, but is now firmer, more solid and generally shinier.

Before

After

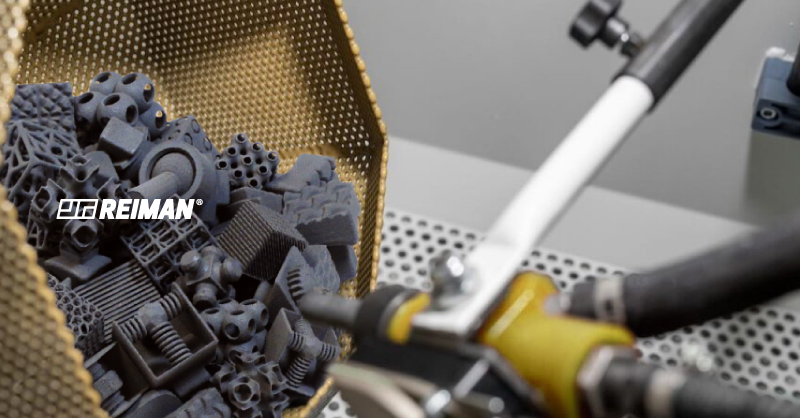

Blasting

Blasting is a finishing process exclusive to EON PA12 and EON PA12-GF, for SLS. This finishing method consists on mechanical surface treatment of parts by the action of abrasives. In-house developed recipes of media allow an effective smoothing or cleaning of AM parts.

The surface texture becomes smoother and more uniform after finishing. Unlike polishing, the surface will not appear shiny to light. It will just be free of any loose dust remains.

Before

After

Vapor Smoothing

Vapor smoothing is a surface treatment process that requires the management of temperature, pressure and specific solvents, applied exclusively to EON ABS/ASA and EON PA12. This finishing process smooths evenly in all kinds of surfaces on AM parts.

The surface is subjected to a chemical melt provided by vapor. The effect of the chemical melt is to reduce the surface texture and make it smooth and level, but without damaging the geometric shape of the product. Along with smoothing the texture, chemical fusion also enhances the overall appearance of the product, giving it a shinier surface texture.

EON ABS/ASA

Before

After

EON PA12

Before

After