We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

What is generative design?

The world and technologies are advancing at a galloping pace. Everything that ins’t technological ceases to be interesting and becomes obsolete. This is an evolution that has been reflected in all kinds of sectors, even the most unthinkable. All industrial activity has undergone a revolution in what is the integration of technologies in different markets.

When you think about design, you automatically think about creativity and usefulness. Yes, design has the main objective of combining creativity, drawing and the idea with a product that is functional and useful. Until the ideal product is found, dozens and even hundreds of prototypes are created where every detail of the most different variables is studied. These processes are long, cumbersome, and can even be very stressful. It is a key part for a certain product to work.

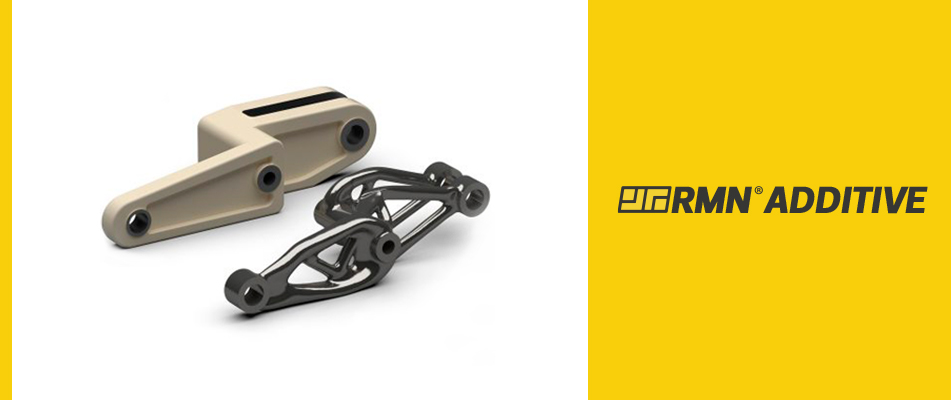

It is in this sense of thinking that the need to approach and explore generative design arises. This is a totally facilitated process that has the ability to generate independent design proposals through a software. That is, product designers, engineers, etc. are able to obtain product solutions by entering into the software the variables they want the final product to have (weight, size, applied forces, fixings, materials, etc.). After inserting these data, it is possible to have access to a huge set of suggestions and possible combinations for a specific solution.

Main Advantages:

- No barriers

This is a process that gives all possibilities and a few more, so there are no limitations since the software can present solutions that were not previously idealized by anyone.

- Time-Saving

Generative design offers immediate solutions, which makes it possible to work on more than one project at the same time, since the time spent on each project is much shorter. Besides this, no time is wasted designing several options for one prototype, since the software already gives all the possible and imaginary options.

- Cost savings

As this is a process that facilitates the finding of solutions, there is no need to spend money and resources on several people for the validation of the prototype. In other words, before a prototype had to be evaluated by different areas and with the generative design it's all simpler, which ends up freeing resources for other projects and investments.

- No faults

While the human hand has more tendency to make mistakes, in a computer this almost never happens. As the processes are all automated the probability of solutions having mistakes is almost zero, unless the variables entered by the user are wrong, but even then the "fault" is not of the computer.

- Versatility

Finally, we highlight the versatility of generative design. This process can be applied in the most varied areas to obtain all kinds of product prototypes and thus become applicable to all solutions.

RMN Additive offers this and other complementary services to additive manufacturing. Contact us and find out the options available.