We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Case Study: How REIMAN Aluminium Profiles Optimized a Client's Assembly Line

In today's competitive manufacturing landscape, optimizing production efficiency is paramount. Assembly lines are the backbone of many production processes, and optimizing their functionality is crucial for maximizing output and profitability.

At REIMAN, we are passionate about helping our clients optimize their production processes and achieve their goals. We believe that aluminium profile structures offer a game-changing solution for assembly lines, providing a level of versatility, efficiency, and cost-effectiveness that are incomparable to traditional welded steel systems.

Building the Perfect Fit

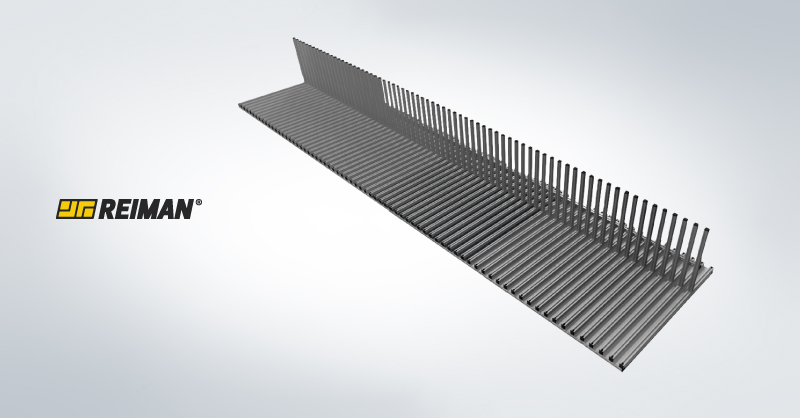

When we were asked to develop an aluminium profile structure for an assembly line, we immediately looked to comprehend our client specific needs and develop a customized assembly cell solution.

We rigorously selected the appropriate aluminium profiles and accessories to create a custom design that optimized workflow and accommodated their production processes. This modular design allows for easy reconfiguration in the future, ensuring adaptability to any changes in production requirements that may arise.

The assembly cell core components include:

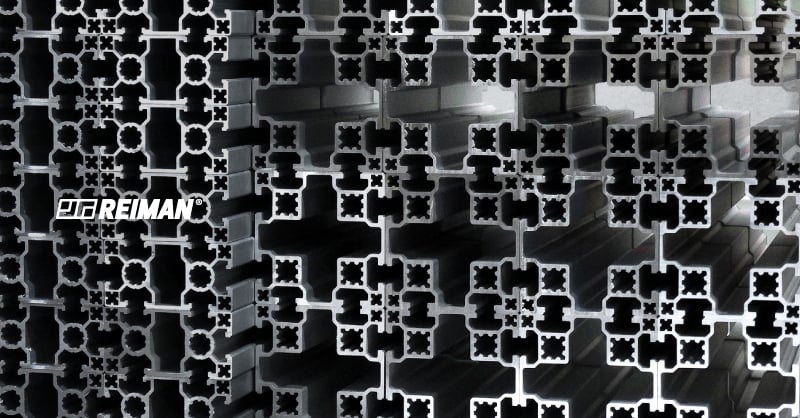

REIMAN offers a comprehensive range of aluminium profiles in various shapes, sizes and thicknesses, catering to different weight capacities, functional requirements and aesthetic preferences.

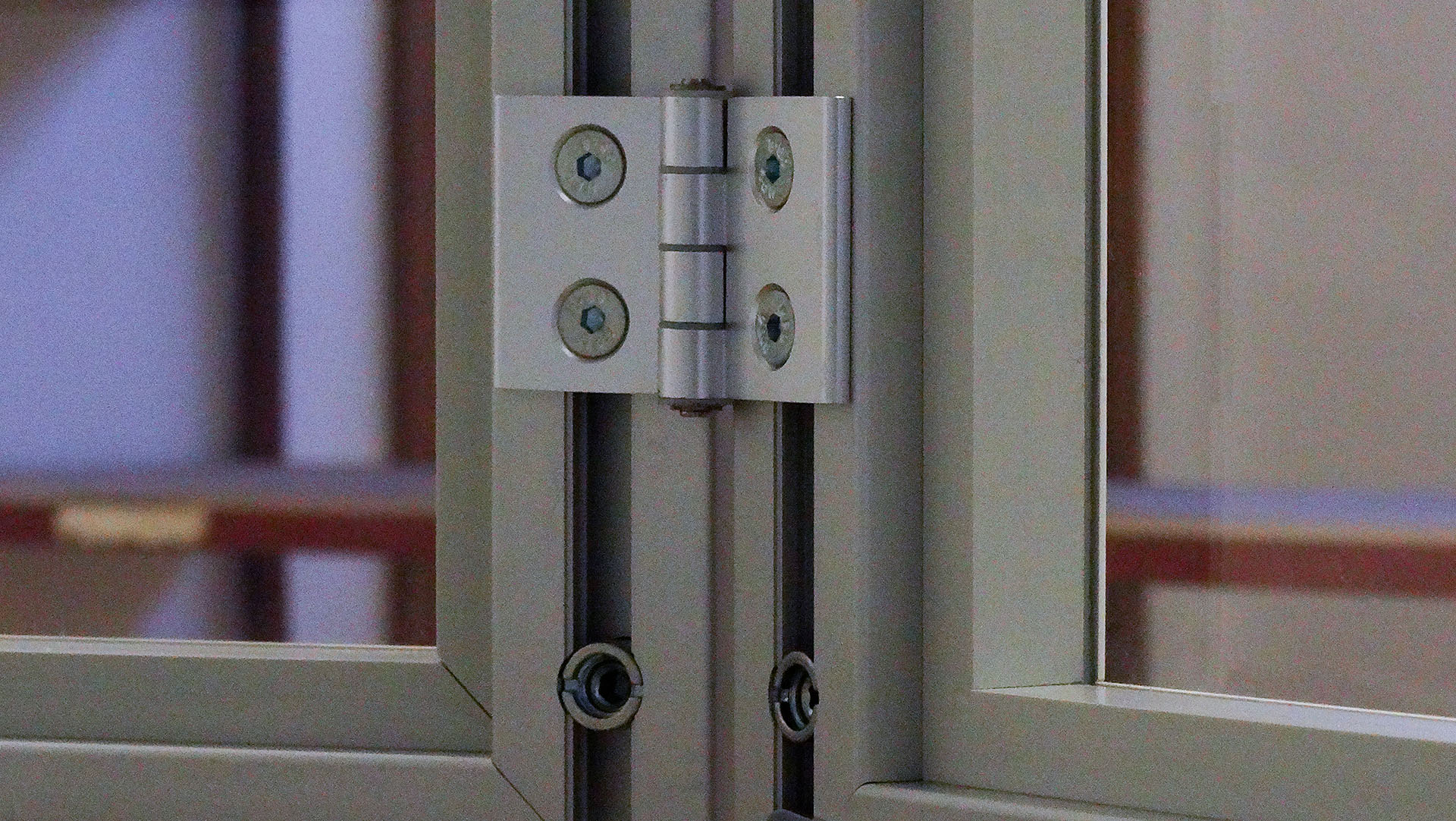

A wide range of accessories, such as screws, connectors, caps, levelling feet, hinges, among others, enhance functionality and ergonomics. REIMAN's extensive library of accessories includes fastening, connecting, covers, floor, panel, door/window and special applications accessories.

The Advantages of Aluminium Structures

Here's a glimpse into the key benefits of incorporating an aluminium profile structure into our client assembly line:

- Increased Efficiency

This assembly cell is more than just a static structure. It can be effortlessly expanded, reconfigured, or relocated to adapt to changing production needs.

- Improved Ergonomics

At REIMAN, we understand that a well-designed assembly line not only optimizes production but also prioritizes workers well-being and safety. That's why ergonomics is a fundamental principle in our aluminium profile solutions.

- Boosted Safety

Safety is essential in any production environment. In this specific case, our aluminium profile assembly cell structure incorporated several design features that contributed to a safe work environment, such as doors and access control and the structure itself is an enclosure.

- Cost-Effectiveness

Aluminium structures offer a long service life, minimal maintenance requirements and the possibility of reuse, leading to significant long-term cost savings. Unlike traditional welded steel structures, aluminium profile structures require minimal maintenance. Furthermore, as production needs evolve, the modularity of the system components to be reused in new configurations, eliminating the need for entirely new structures.

| Cost | Modular Aluminium Profile Structures | Welded Steel Structures |

| Material | €€€ | €€ |

| Installation | € | €€€ |

| Maintenance | € | €€ |

| Cost | Modular Aluminium Profile Structures | Welded Steel Structures |

| Material | €€€ | €€ |

| Installation | € | €€€ |

| Maintenance | € | €€ |

| Cost | Modular Aluminium Profile Structures | Welded Steel Structures |

| Material | €€€ | €€ |

| Installation | € | €€€ |

| Maintenance | € | €€ |

| Cost | Modular Aluminium Profile Structures | Welded Steel Structures |

| Material | €€€ | €€ |

| Installation | € | €€€ |

| Maintenance | € | €€ |

The Results: A Transformed Assembly Line and Enhanced Productivity

The implementation of our aluminium profile assembly cell benefited the client's production process. They praised the flexibility, safety and cost-effectiveness of the system.

This successful project solidified our partnership with this client.

At REIMAN, we are committed to helping our clients achieve their manufacturing goals through aluminium profile solutions. Our knowledge and expertise in this area, coupled with our dedication to client satisfaction, makes us the ideal partner for your challenges.

Contact us to discuss how we can help you optimize your production processes with our aluminium profile systems.