Interview with Ricardo Ferreira: Key Trends in the Industry for 2025

We have Ricardo Ferreira, Product Manager at REIMAN, with us to explore his perspectives on the future and trends for 2025 in the industrial sector.

Ricardo, how do you see the future of the industry in Portugal and worldwide?

In my opinion, the future of the industry in the coming years is, at its core, the continuation of the disruptive trends that are already underway.

We hear a lot about terms like digitalisation, automation, artificial intelligence, IoT and Industry 4.0 and the truth is that these concepts are already being implemented in many sectors, all over the world.

What we will experience in 2025 will be an acceleration of these processes, allowing for greater precision, efficiency and safety in operations and production processes.

How has REIMAN kept up with these changes?

At REIMAN, we have accompanied these transformations strategically, with an approach that combines innovation, know-how and proximity to our partners and customers.

Our focus is on constantly improving our internal processes and maintaining a high and diversified stock of products, with thousands of references available in our main departments: operating and machine parts, linear motion, power transmission, and aluminium profiles.

This approach allows us to respond quickly to our customers' needs, with excellent cost/benefit advantages.

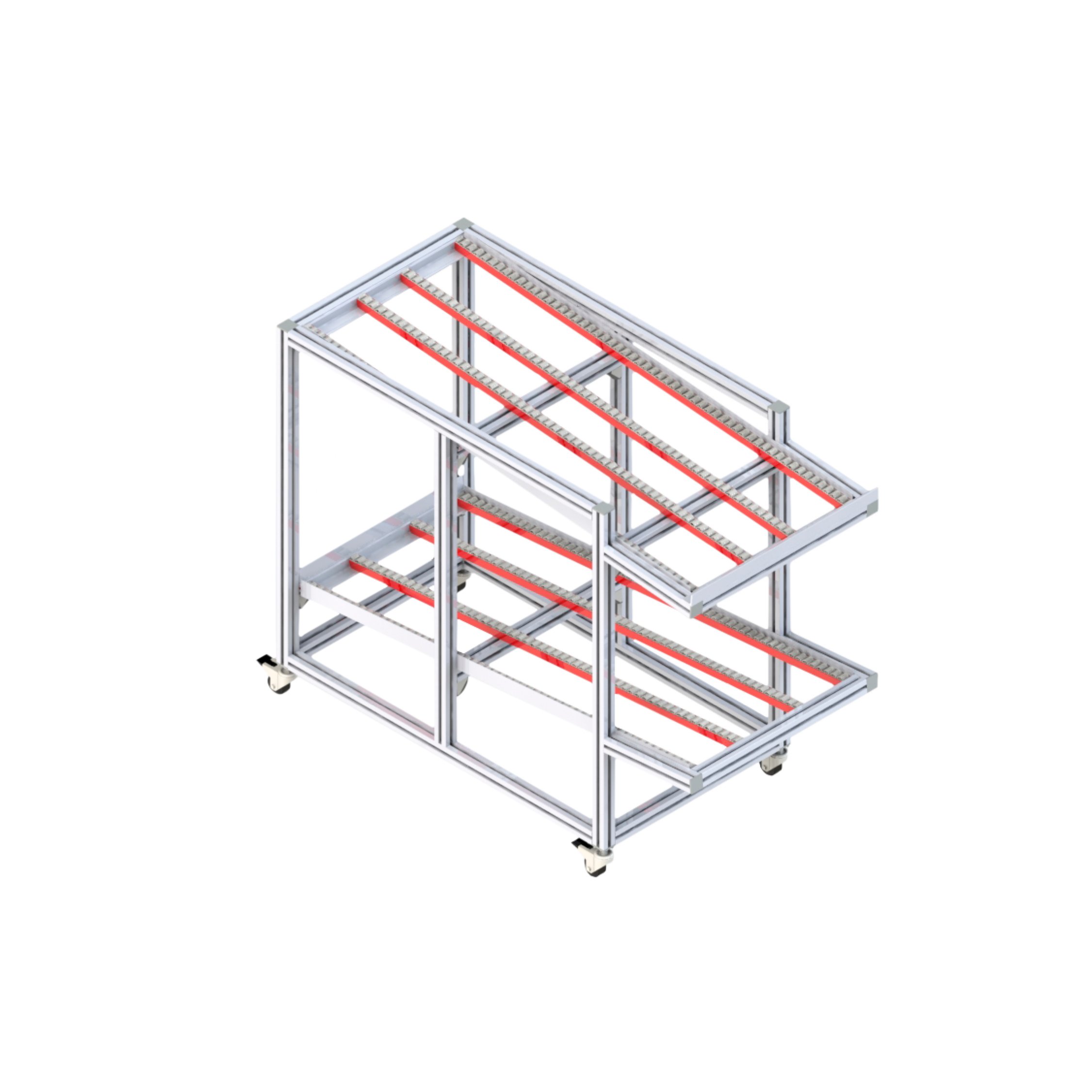

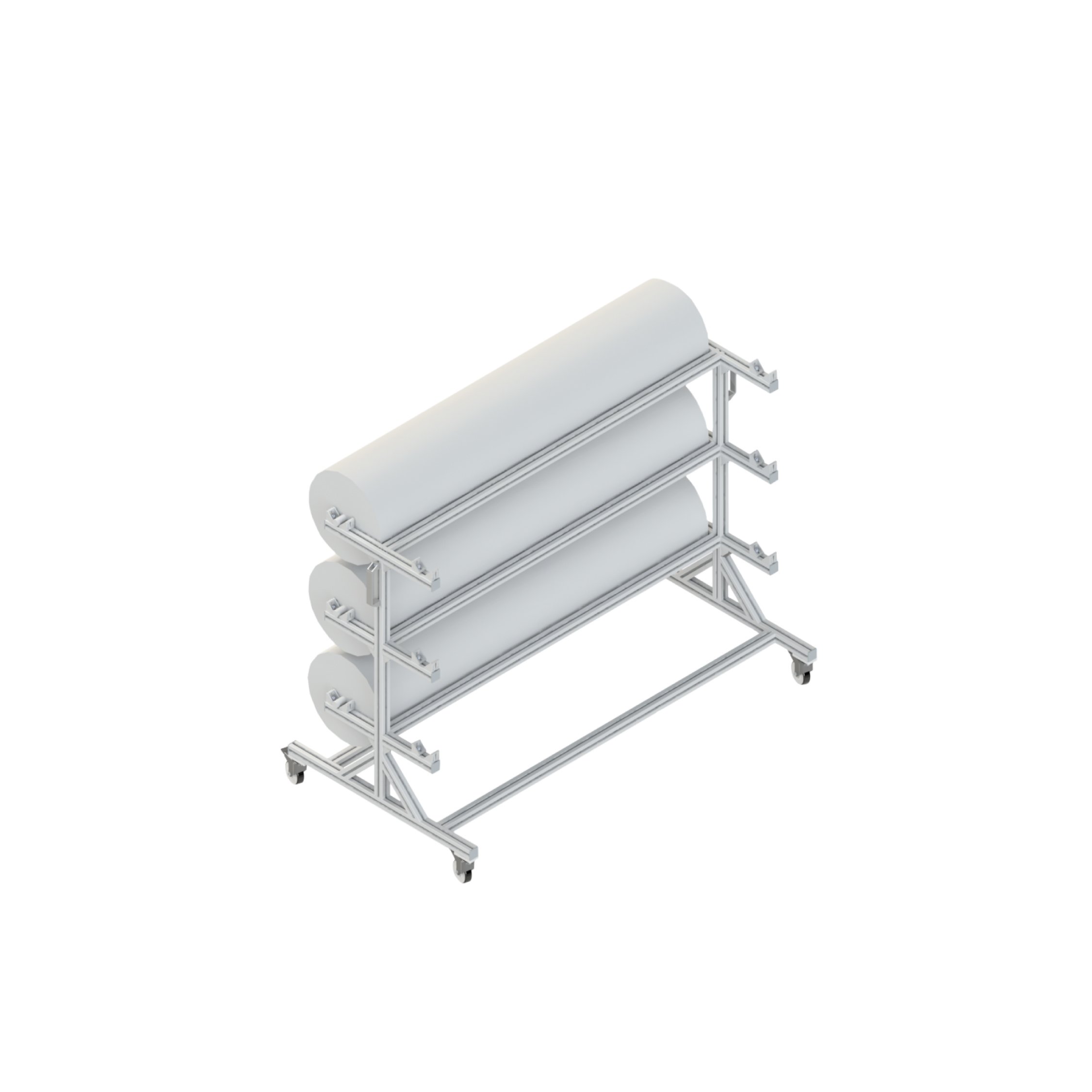

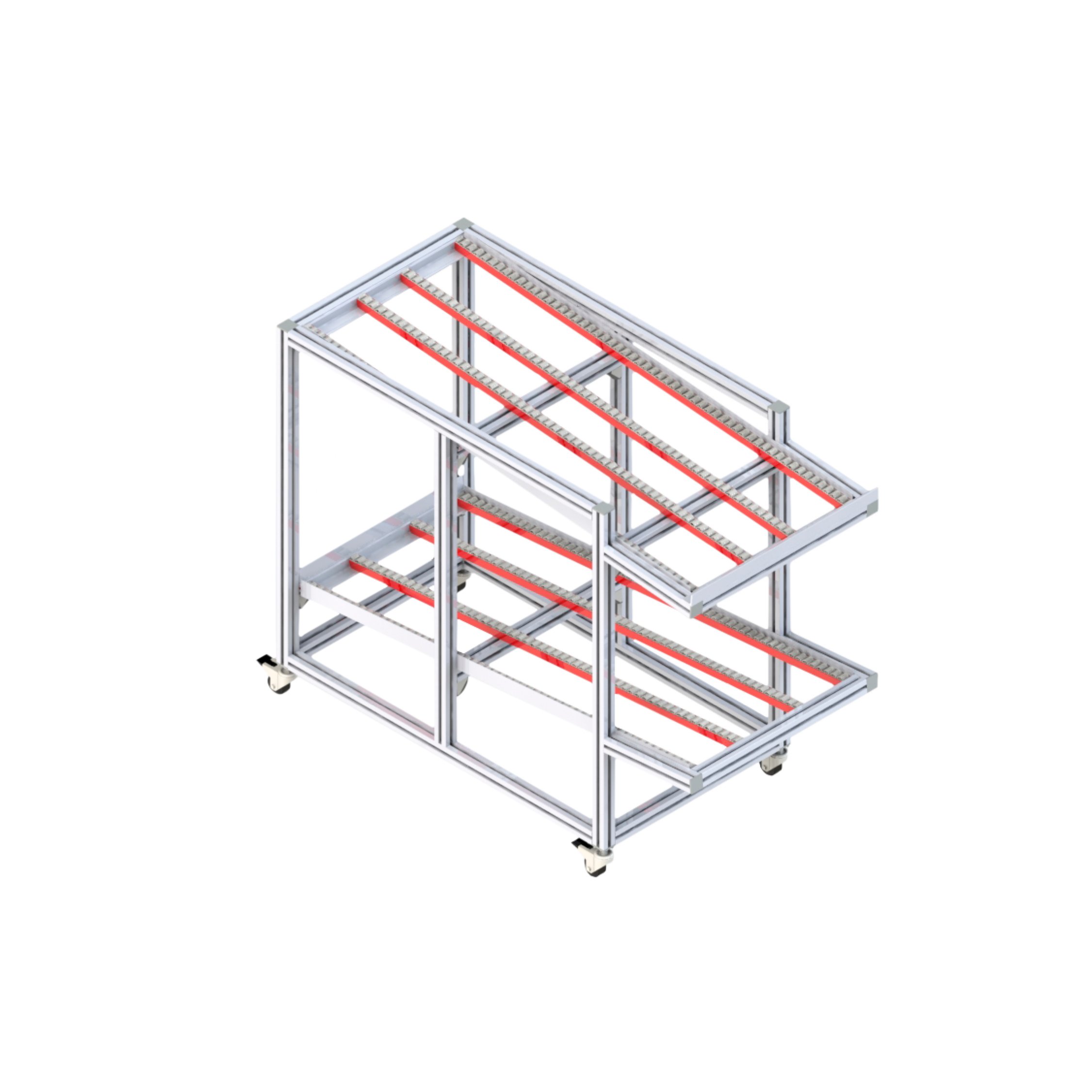

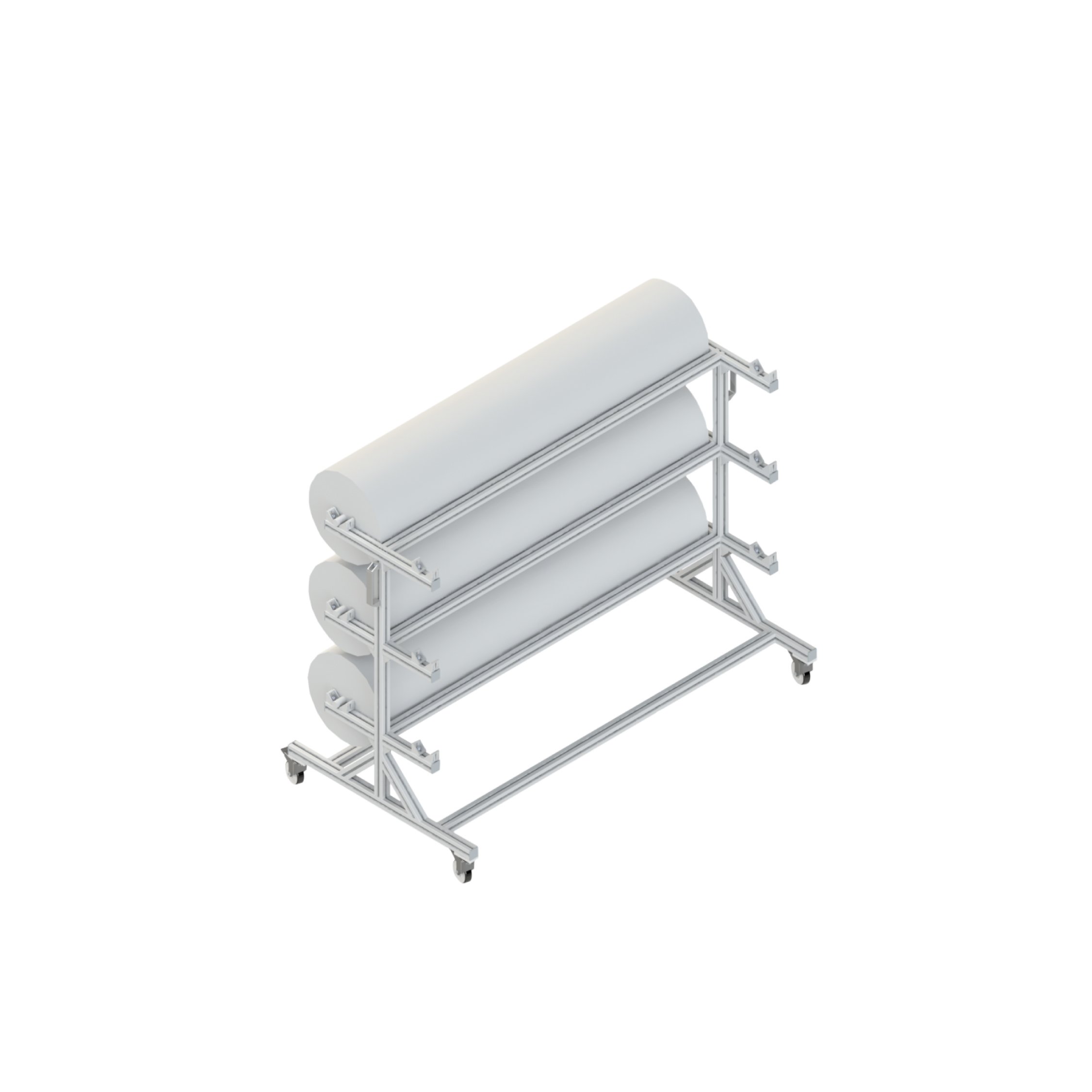

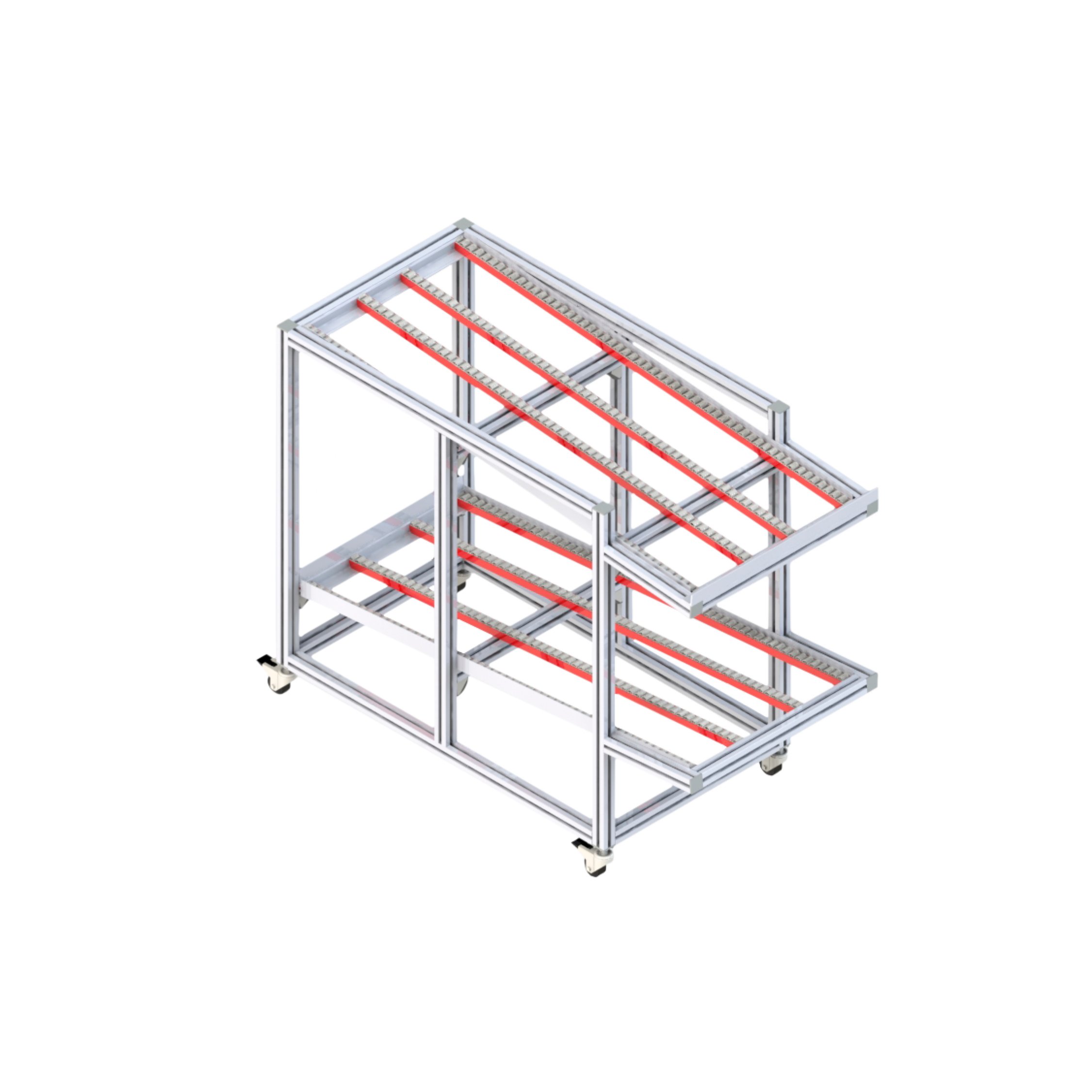

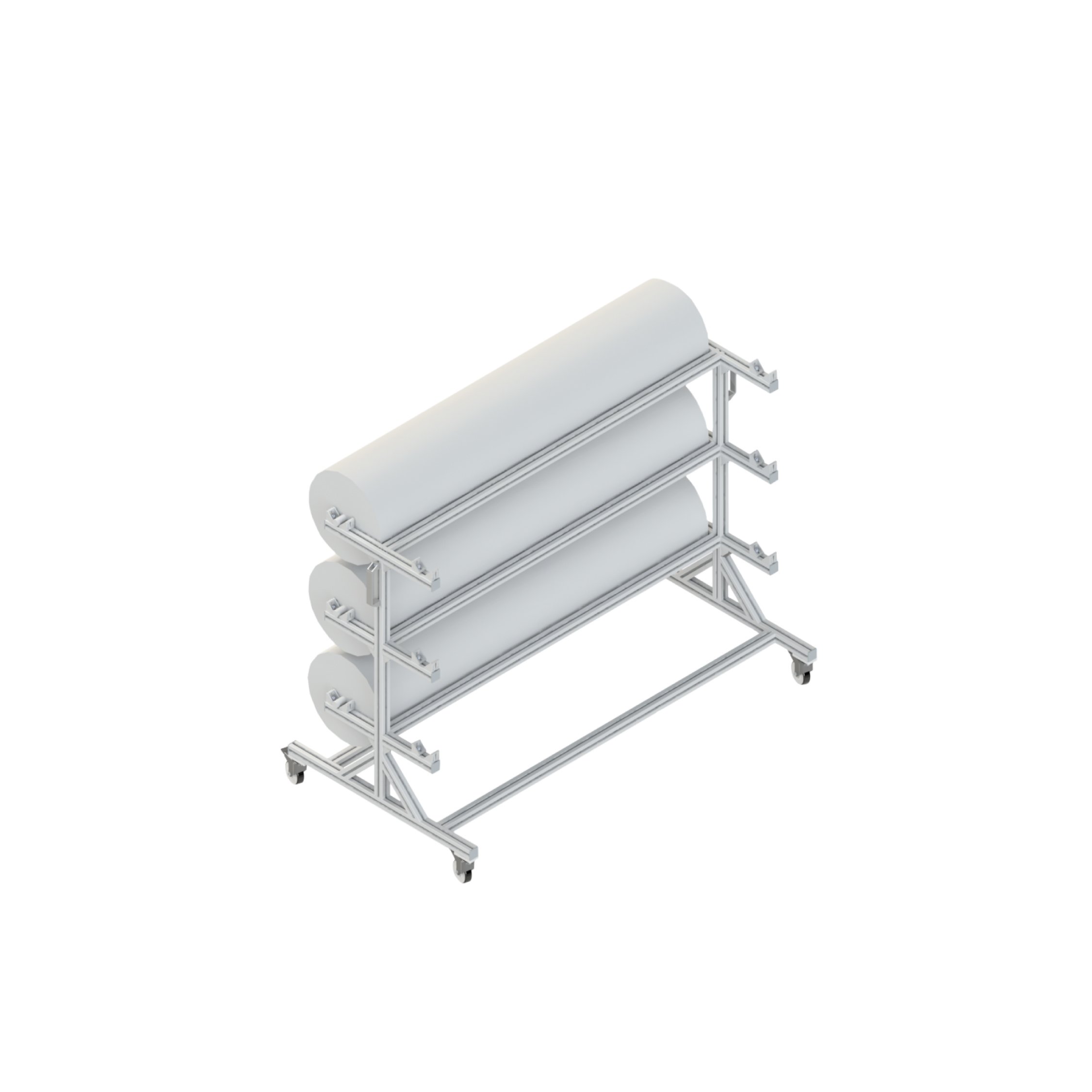

For instance, I would highlight our extensive range of Wolweiss aluminium profiles, which stand out for their versatility, adaptability, flexibility, and ease of integration into various industrial applications, including the configuration of modular structures for production lines, workstations, and more.

Drop-off and Pick-up Point

Workbench

Support Structure

Drop-off and Pick-up Point

Workbench

Support Structure

Drop-off and Pick-up Point

Workbench

Support Structure

Do you think the term ‘smart factories’ gives a name to what we will increasingly experience?

Without a doubt, smart factories are becoming the norm and represent the future of industrial production.

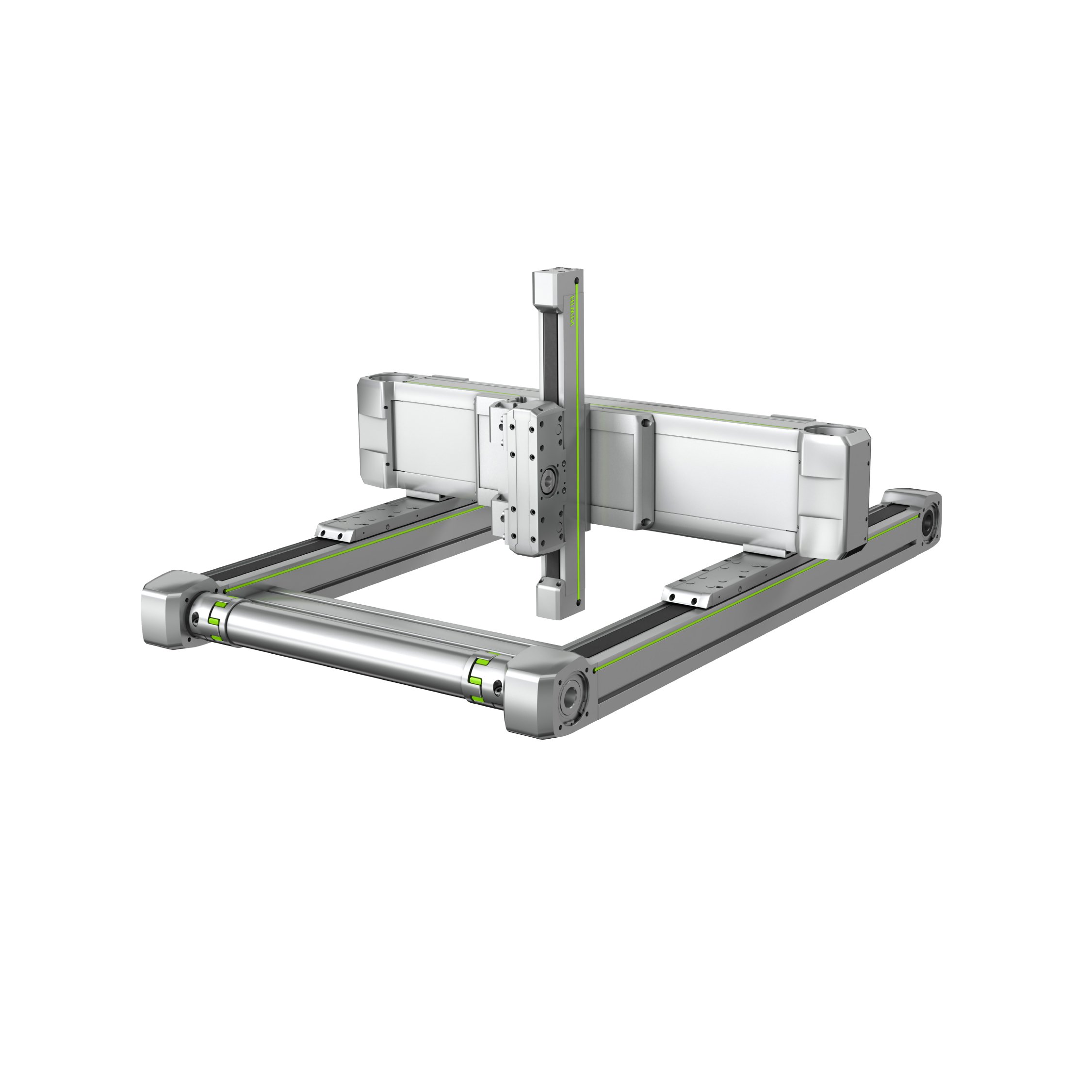

At REIMAN, we supply essential components for these operations, such as Hiwin modules and linear actuators that enable precise, backlash-free movement with low operating noise. Accuride's electric slides also provide reliable movement for automated solutions,

as well as Dirak's accessories for mechatronics, which improve safety and the transmission of information in real time to the equipment.

With these innovations, it becomes possible to optimise processes and reduce waste, which is especially important as sustainability is now a top priority.

As you mentioned, sustainability is an increasingly important topic. In your opinion, how can the industry become more sustainable?

Sustainability in the industry goes far beyond energy efficiency. It also involves extending the lifespan of equipment, avoiding unnecessary downtime, and minimising waste.

At REIMAN, we supply components that not only maximise efficiency and reliability, but also extend service life, minimising the need for constant maintenance and replacement.

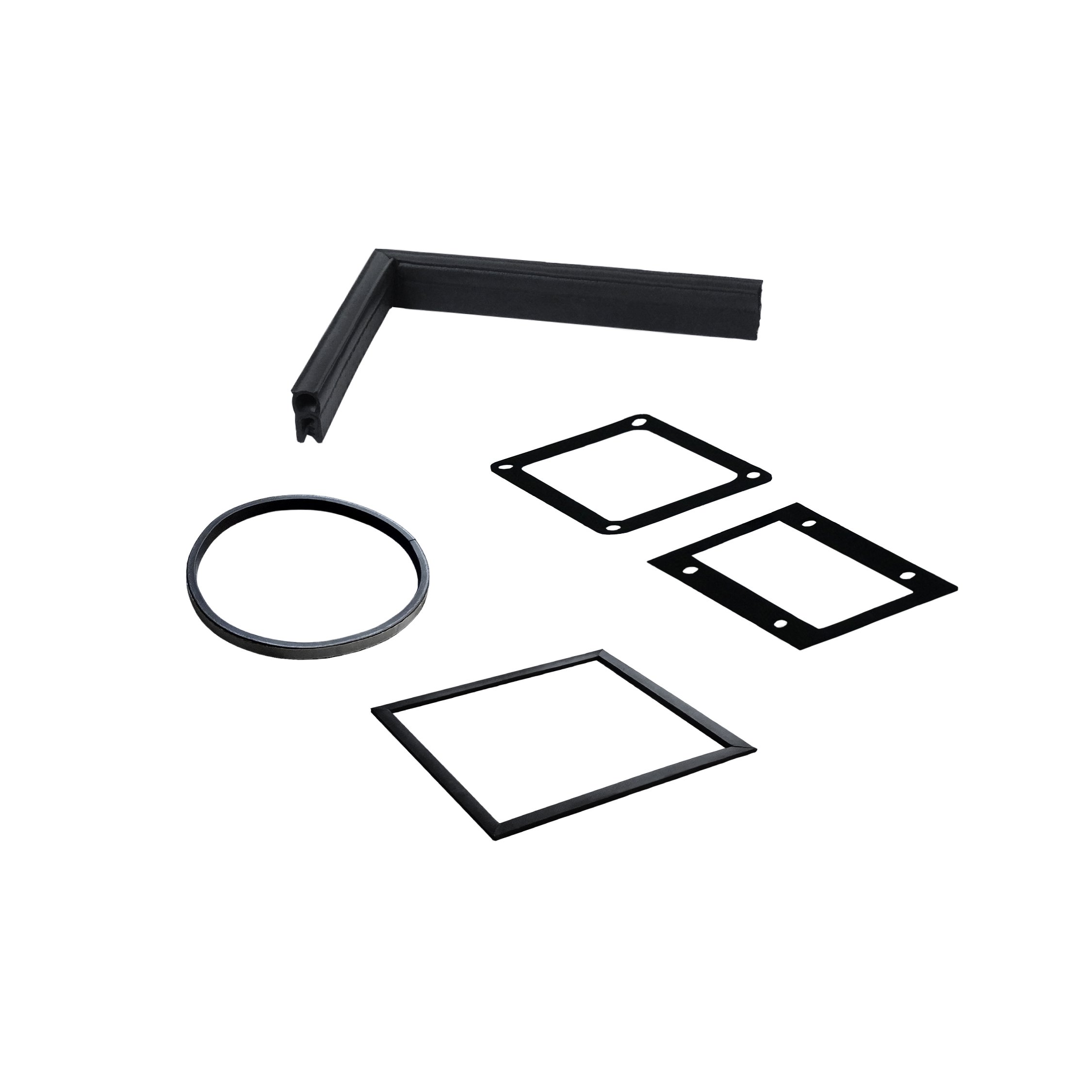

Examples include Bernati's IE4 electric motors that achieve an efficiency of around 97%, Invertek Drives variable frequency drives that control and optimise the speed of electric motors, Dirak edge protection profiles that prevent water, dust and other contaminants from entering, protecting internal components. Stainless steel products, for example from Elesa+Ganter's Hygienic Design range, which contribute to reducing the environmental footprint by being easy to clean, reducing the waste of water, energy and environmental contaminants such as detergents.

In recent years, additive manufacturing, more commonly known as 3D printing, has become an increasingly popular technology in industry, almost becoming mainstream. What is your opinion of this phenomenon?

Undoubtedly, additive manufacturing has been changing the way we approach the production of parts. In my view, the main advantage of this technology is its ability to create complex and customised geometries that would be impossible or extremely expensive to produce with traditional methods.

At RMN Additive, a branch of REIMAN dedicated to additive manufacturing, we have cutting-edge technologies and over 20 materials available to meet the market's demands for flexibility and adaptability, offering 100% customised solutions.

Ricardo, to conclude, what advice would you give to companies looking to adapt to these changes in the industrial sector?

Changes in the industry require a proactive and strategic approach. We are moving towards a future where factories will be smarter, solutions more personalised and production more efficient.

At REIMAN, we are committed to being a strategic ally in the success of our customers, partners and suppliers.

Thank you very much, Ricardo, for your availability and for sharing your perspectives and knowledge with us.

The pleasure is mine, thank you for the opportunity.