Advantages of Robotics in the Food Industry

Automation is increasingly having a positive impact on companies, especially when they are looking to scale up their business. One of the key differentiating factors between successful manufacturers and their competition is precisely the ability to get their products to market quickly while keeping costs down. Automation of high throughputs brings many benefits to product processing and manufacturing, such as flexibility, accuracy, and consistency. When considering the use of robots for a production line, the choice of the optimal gripper (also known as gripper or EOAT, end-of-arm tool) is critical to ensure increased production, and so when industrial robots use the wrong gripper (EOAT), good results become less likely.

For an industrial robot to achieve the best possible performance, the gripper must be able to effectively complete the most demanding work. In high-speed operations, the gripper is the star of the show and therefore must grip and position products without damaging them, quickly and precisely. Sometimes it is unavoidable that there is a constant danger of product damage in high-speed processes because without a suitable grasp the products can slip, fly or fall off. A reliable grasp will allow the robot to move at higher speeds without such incidents occurring.

Unreliable grasping is the main reason why manufacturers are unable to grow their business through automation and/or robotics. Choosing the right gripper will ensure higher levels of productivity, throughput, and a quick ROI. Manufacturers need an adaptable tool that can handle products at high speed and safely without damaging them.

Not all grippers are created equally, so making the wrong choice can significantly reduce productivity, which is not ideal in an automation process. To increase throughput, the operations should be carried out in such a way as to avoid any downtime in the processes as much as possible.

One of the challenges that manufacturers face is the correct processing and handling of products. If we are handling a single type of product, there is no need for a tool change, but if on the contrary, we are dealing with a multi-product line, or if products vary in shape, size or weight, manufacturers do not have time to build a new solution for each product reference, or for each variability that is introduced in the production line. To maximize production and optimize investment, manufacturers need a solution that can handle a wide variety of products while keeping their production level high. With the know-how of a company like REIMAN combined with a product like Soft Robotics, the variability problem has been solved, as this technology allows for the picking and positioning of varied products using only one tool - the mGrip. With unlimited flexibility, it is possible to build a tool that adapts to the production needs, and not the opposite.

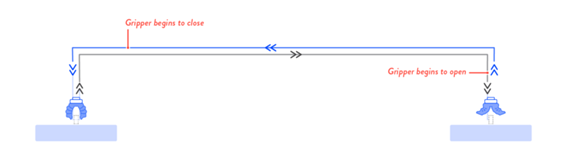

REIMAN has production applications capable of running more than 180 picks per minute (picks per minute, PPM). We can best understand how to achieve this speed by looking at the pick rate. The pick rate is the number of picks and positions that a robot can do per minute, with a given tool/EOAT. Soft Robotics' "soft" grippers can open and close 3-4 times per second, which is even faster than the movement of a human hand. To demonstrate how fast this movement is, you need to look at the dwell time, pick location, and movement time. The mGrip can start closing before it gets to the product (pick location), and open before where it will drop it, thus eliminating dwell time.

High-speed operations require a gripper that can keep up with the speed of the robot. A gripper that can firmly grip products with different characteristics and quickly adapt to products in real time will certainly achieve higher pick rates and decrease dwell times. An industrial robot coupled with the mGrip will help companies achieve the desired throughput.

5 advantages that mGrip brings to the food industry

In the last years some solutions have been developed in the area of robotics for food processing and handling, but there is still a gap that seems to resist this technology - the packaging technique. There is a great difficulty in finding an automated solution that is able to pick up food without crushing, breaking, or even dropping it at the time of packing it. Following this problem, REIMAN claims to have the ideal solution, the mGrip from Soft Robotics, thanks to its fully adaptable silicone grips.

REIMAN and Soft Robotics develop and produce an innovative handling technology that allows automation of complex processes that have remained manual until today, simulating the human hand.

REIMAN's expertise and superior and proven experience make it the only company in Portugal that truly specializes in robotic handling of food products.

Get to know the main advantages of this technology:

- Speed and productivity

The mGrip has a huge capacity to work at a very high rate. It can therefore achieve higher throughputs and increase production, as well as relieve the pressure caused by labor shortages and reduce labor costs.

- Safety

When it comes to food processing and handling, there are regulations around the world that help manufacturers realize which tools and materials are safe for contact with food. This technology complies with several food regulations, including EC 1935/2004 and FDA CFR Title 21, along with being built following GMP (Good Manufacturing Practices) standards. This means that the gripper has been designed with food safety in mind, to minimize the risk of pathogens spreading, and is protected against bacterial penetration and contamination.

- Smoothness

The mGrip is distinguished by the fact that the grippers are entirely produced with a proprietary silicone that does not damage the product, unlike the usual grippers present on the market that are usually made of stainless steel or plastic. These "traditional" grips, either due to their recurrent lack of softness, low sensitivity or poor adaptability in handling, often end up marking or damaging the product, and although it is often not visible at the time, it ends up leading to claims and heavy costs for the manufacturer.

- Versatility

The versatility of this system allows it to be applicable to various industries, such as food, pharmaceutical, consumer goods, among others. This technology provided by REIMAN adapts to the product, even when it changes size, shape or orientation, that is, it absorbs the variability intrinsic to the product and the process. In addition, it can handle delicate objects up to 180ppm (products per minute) without causing damage.

- Profitability

Finally, the combination of all these advantages results in the greatest of all - increased profitability. The fact that it's a faster, safer (avoiding less damage) and more versatile technology makes mGrip very cost-effective in the short term and allows far more consistent results to be achieved.

Contact us for more information about this innovative technology or to make a test with your product!