We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

What types of Operating Elements are most commonly used in industry?

Embraced in the generic portfolio of Operating & Machine Parts, Operating Elements are very important, allowing the manual drive in many industry sectors. Due to this fact, it's necessary to ensure the product in hand to be perfectly adapted and ergonomic for manual use.

Elesa+Ganter's handwheels and crank handles are well thought, designed and produced to correspond to its necessitites of any workplace, suiting the material to its composition and the way they must be driven.

These are the types of handwheels and crank handles applied in the industry:

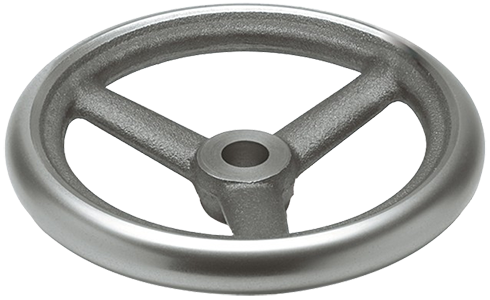

Spoked Handwheels

Spoked handwheels are operating elements frequently applied in multiple industries, controlling, for example, positioning levels, pressure or tension in different components such as valves or adjust cutters. These handwheels are suitable for adjusting clamping measures and heavy torque.

Spoked handwheels are produced in many highly resistant materials such as aluminium, technopolymer, cast iron, duroplast, and, in case of corrosion-exposed environments, stainless steel. These handwheel products are available from 80mm to 375mm in diameter, and their structure varies between an implemented handle, either fixed, revolving or fold-away handle, or a handwheel without handle.

Spoked Handwheel without Handle

Solid Handwheel with Fold-Away Handle

Solid Handwheels

Solid handwheels are applied in many sectors, such as food, textile or medical industry. The covered shape of a solid handwheel allows more sfety between the applied structure and who maneuvers it, with the intention of preventing any accident.

Just like spoked handwheels, the same materials are appropriated to solid handwheel production, and their structure also varies either with a handle or without it. Another feature from solid handwheels, is the extended hole in the center of the handwheel, in order to allow a practical assembling on the spindle, according to each application's requirements. These handwheels are available in various products, with diameters between 50mm and 350mm, and the hole size between 8mm and 108mm.

Arm Handwheels

Arm handwheels are operating elements designed to obtain an agile and precise adjustment. These handwheels are fit to control the functioning of a machine, as well as maneuvering a strong clamping measure and fixing it. The handwheel varies between two, three or four arms, and the arms' collective structure ensure a necessary force to control the application at hand.

Materials appropriated for arm handwheel production are technopolymer and duroplast. Steel is also used for arm production, in some products. About the arm handwheel shape, the diameter determines the necessary strength for an application. With that, the arm's length in these handwheels vary between 170mm and 400mm of external diameter. For a perfect fit, adapted to the equipment at hand, the hole size in these handwheels are available in 10mm, 12mm and 20mm.

Handwheel with Four Arms

Fixed Crank Handle

Crank Handles

Crank handles are applied in environments that require frequent changes in adjustment, just like in lathes, milling machines and other machinery equipments. They are conceived in light materials and practical for its intended function.

Crank handles are produced in materials such as polymer, phenolic plastic, aluminium and stainless steel. The crank handles' external diameter in catalog are placed between 65mm and 500mm, and the impremented handles vary between 52mm and 252mm in length. The handles can be either fixed or a fold-away type, considering the most suitable way for each application.