Solomon - Machine Vision with Intelligence

Solomon is a machine vision solution, developed with native artificial intelligence. A new approach to solving difficult problems in Industry.

Solomon is a multinational company, founded in 1973, and listed on the stock exchange since 1996. Its core business is advanced machine vision systems. Reiman is the official representative of Solomon products in Portugal.

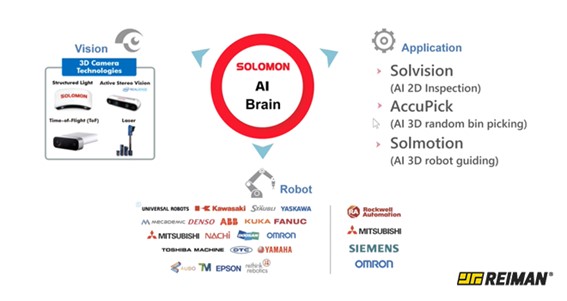

We can consider the Solomon solution as a software. A powerful and intelligent software that has been divided to create several specialized machine vision by-products. All of them have a common characteristic, the native artificial intelligence.

Remembering that Artificial Intelligence is the science that makes machines think and make decisions like a human being, Solomon products add great value to our customer's equipments, solving complex problems with agility.

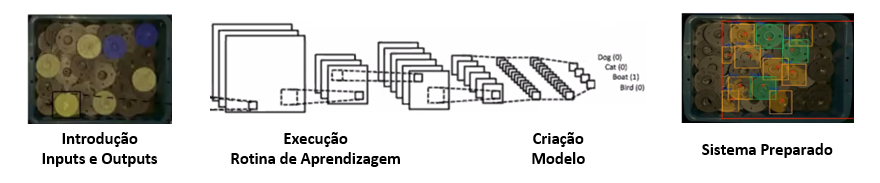

Solomon products have at their core several machine learning algorithms, which is a subfield of artificial intelligence. This allows the traditional approach of decision making based on mathematics and pre-defined logic, to be overcome by a learning approach based on inputs and outputs, which will create a representative model of the objective, that will respond even to new and untrained inputs.

Some examples of 'type' applications where artificial intelligence in vision systems is especially advantageous:

- Applications where in addition to identifying the shape of the part it is necessary to verify its color, inscriptions, images and even textures. Information acquired in 2D and 3D, sometimes simultaneously.

- Applications where the object has variations intrinsically or during production, and therefore its shape is not consistent. Examples: Food, flexible elements, textiles, etc.

- Applications where the product format is complex and/or are overlapping and tangled, giving rise to complex information.

- Applications with transparent, translucent or shiny objects, where the incidence of light creates difficulties in their identification.

- Applications where it is necessary to identify and analyze several different types of formats/packages, even together.

AccuPick

Solvision

Solmotion

Bin Picking that is agile, fast, precise, and intelligent.

With capabilities above average.

This product is subdivided into 3 (2D, 3D and Smartpack).

All of them allow to identify randomly arranged product(s) and control the robot to safely pick the best valid option available at each moment.

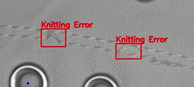

Quality inspection in products with characteristics where the traditional "rule-base" approach does not work.

This product allows you to perform quality analysis even when there is no clear and/or complete definition of the defect(s).

Here artificial intelligence allows you to identify and classify the features and anomalies like human vision.

Ensuring synchronism between the robot's movement and the object's 3D position at each moment.

This product will identify the random position of an object, even without seeing it completely, and guide the robot to perform its task without the need to fix or correct the object's position.

Bin Picking that is agile, fast, precise, and intelligent.

With capabilities above average.

Quality inspection in products with characteristics where the traditional "rule-base" approach does not work.

Ensuring synchronism between the robot's movement and the object's 3D position at each moment.

This product is subdivided into 3 (2D, 3D and Smartpack).

All of them allow to identify randomly arranged product(s) and control the robot to safely pick the best valid option available at each moment.

This product allows you to perform quality analysis even when there is no clear and/or complete definition of the defect(s).

Here artificial intelligence allows you to identify and classify the features and anomalies like human vision.

This product will identify the random position of an object, even without seeing it completely, and guide the robot to perform its task without the need to fix or correct the object's position.

Podemos identificar exemplos de aplicações alvo para cada um desde produtos:

- Accupick

- Solvision

- Solmotion

The Solomon solution is extremely versatile and adaptable to the main peripherals of the market. In other words, it is not a solution that restricts its Customer to the peripherals of the brand itself.

This fact applies to robots, where Solomon has an interface created and tested with more than 20 of the main brands of robots on the market, where it is only necessary to specify the IP address of the robot and its brand. Allowing a Master control, the Solomon software controls the robot itself, with no need for extra programming, or a Slave control, where all information achieved is sent to a PLC or to the robot controller, which in turn will control the movements of the robot.

Following this logic the interface with the PLC is also guaranteed, by the same way. That is, the Solomon software ensures the interface with the main brands of PLCs on the market, simply by identifying the brand, model and again its IP address.

Last but not least, although Solomon has its 3D vision system for sale (SLM 3DRBP), it is not mandatory that it be used. Market options such as the Intel RealSense D450, the Azure Kinect DK or Basler and Teli cameras are also viable options.

Remembering that the Solomon software runs on Windows, once again it is not necessary to purchase a brand specific driver. Our customer will be able to build his computer, with normal market products, according to the requirements of the proposed solution.

In line with the 4th industrial revolution Solomon presents one of its most coveted innovations - The User Interface. Holder of many awards, the most recent being the reddot for the best interface design in 2020.

Based on the No-Code philosophy, it is impressive how quickly a user can parameterize and program the system, with a guarantee of operation at its end.

Some of the key disruptive features:

Flowchart:

Graphical Programming;

Drag and Drop;

Sequence of Instructions;

Available Standards.

Parameterization:

Intuitive interface;

Automatic selection;

Advice;

Advanced options available.

Simulation:

Offline Programming;

Virtual Testing;

Condition checking;

Use of real photos.

Flowchart:

Graphical Programming;

Drag and Drop;

Sequence of Instructions;

Available Standards.

Parameterization:

Intuitive interface;

Automatic selection;

Advice;

Advanced options available.

Simulation:

Offline Programming;

Virtual Testing;

Condition checking;

Use of real photos.

Reiman already has its Innovation Center equipped with Solomon products, where its technical team, properly trained, can help you in your challenge, performing proofs of concept, training and support.