We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Which Accessory Solutions Ensure Food Safety?

The food industry has always been very sensitive when it comes to hygiene and disinfection, since the entire production process through which the food passes has a high risk of contamination. From the raw materials used, to the processing of the food, there is a great need to implement rules and standards that aim to ensure consumer safety.

Companies that sell food products must ensure compliance with EC Regulations, such as the General Food Regulation Act (EC) 178/2002. This law covers all phases of production, processing, and distribution of food and animal feed.

But this concern is not new!

In the European Union every year about 25 000 people die and there is a loss of 1.5 thousand milion Euros with increased health care and loss of productivity, due to Antimicrobial Resistance. The level of Antimicrobial Resistance has increased worldwide due to several factors, among them poor hygiene practices and insufficient infection prevention measures. Thus the food industry can do its part in preventing public health with the use of Antimicrobial materials, such as Elesa+Ganter's San Line.

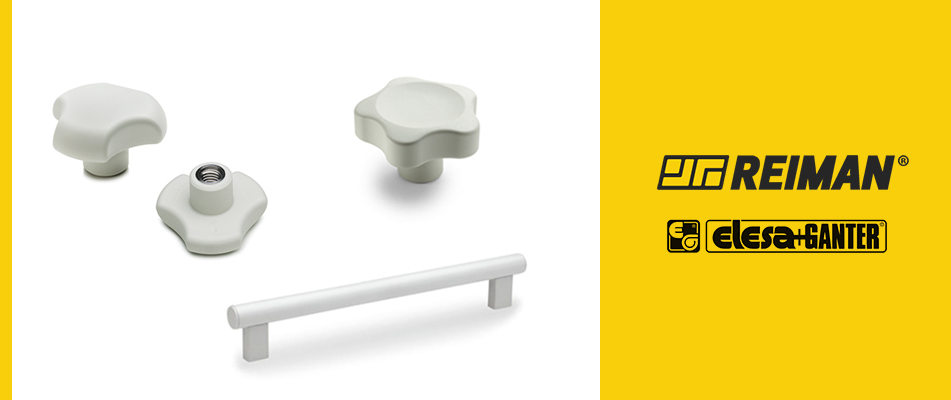

This line of products is primarily designed for medical and hospital equipment, but can make all the difference in the food industry. This line prevents the reproduction of undesirable bacterial organisms that can cause unpleasant odors, discoloration, degradation and biofilm formation on surfaces. This line contains handles and knobs with antimicrobial additives (silver ion source on an inorganic basis without antibiotics or pesticides) or coated with a special finishing material to provide efficient protection against the spread of bacteria.

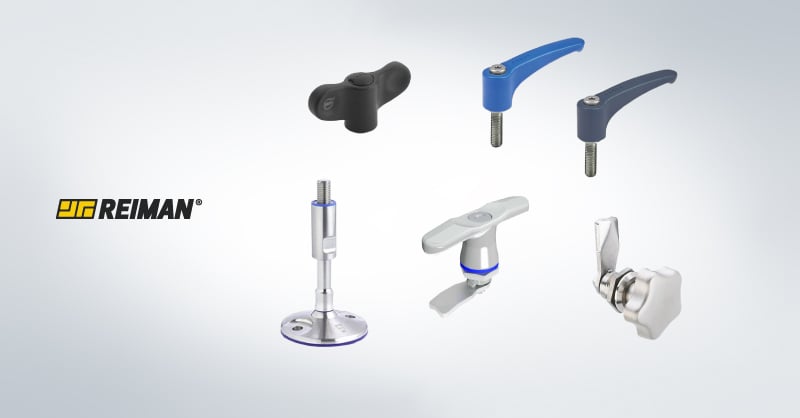

Knowing the importance of sanitizing the production surfaces of companies in the food industry, several solutions have appeared on the market to ensure high food safety standards. Among them are the lines:

This line features fittings with sophisticated geometric shapes made of stainless steel, which prevent any accumulation of bacteria. In order to guarantee the highest levels of safety, the products are designed without sharp edges, thus avoiding any potential handling risk. In addition, they are adaptable to any environment due to their high resistance to corrosion and temperature. These products have specific characteristics tested according to the DGUV standards, and NV 13090 certification.

The Hygienic Design Line of Elesa+Ganter were designed with the aim of ensuring product safety and consumer protection in the food, medical technology and pharmaceutical industries. Due to their specific properties, the standard parts of the Hygienic Design range can assist the production process in these sensitive areas and facilitate the manufacture of preservative-free products. They combine high surface quality, absence of gaps, external surfaces without ledges, and sealed bolt-on areas. A sealing concept based on FEM calculations ensures reliable contact pressure after installation.

This range also means that the time and material required for regular cleaning is significantly reduced - which also significantly reduces operating costs.

This range includes standard components made in technopolymer "signal blue", RAL 5005, a material suitable for food contact (FDA CFR.21 and EU 10/2011), easily detectable and recognizable to the human eye thanks to the specificity and uniqueness of color, which normally does not exist in environments where these components are applied.

The specificity and uniqueness of the blue color, naturally absent in the environment where these components are applied, also allows the visualization and detection of contaminating particles.

This line includes standard components with AISI 303 and 304 stainless steel inserts, made of "blue green" technopolymer, RAL 5001, material suitable for food contact (FDA CFR.21 and EU 10/2011).

The special additive contained in the plastic material allows the detection of 5 mm cubic particles by means of a metal detector.

This range is designed for the food processing, chemical and pharmaceutical industries, for all industries with difficult environmental conditions and for all applications where legal provisions make the use of corrosion-resistant materials mandatory.

The Elesa+Ganter product range includes a wide variety of special AISI stainless steel products in all product groups. It covers standard stainless steel elements and standard technopolymer elements with stainless steel metal inserts, a material that prevents the accumulation of bacteria.

For more information, please contact Reiman’s specialized team.