We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Maintenance and Care of Worm Gearboxes

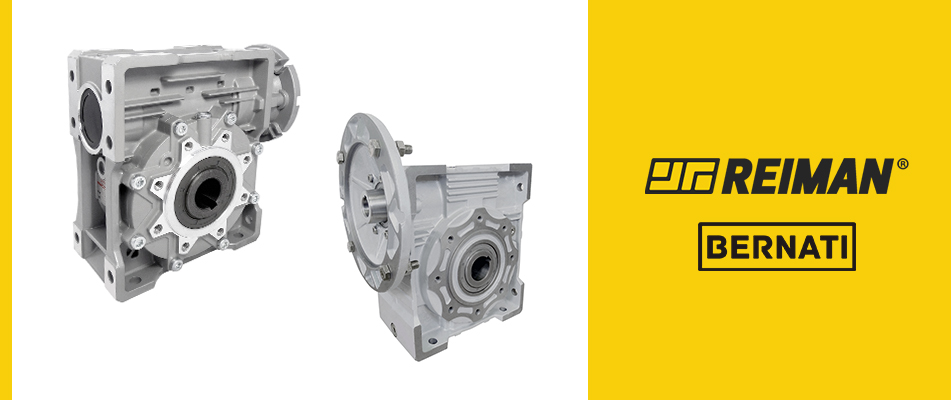

Bernati's worm gearboxes are essential components in many industrial systems and processes, ensuring the efficient transformation of power into motion. To maintain optimal performance and extend their service life, regular and proper maintenance is crucial.

Why is Regular Maintenance So Important?

Regular maintenance of worm gearboxes is essential to ensure the efficiency, durability, and safety of industrial equipment and machinery. By conducting periodic inspections and maintenance, it is possible to prevent failures, extend the lifespan of components, improve operational efficiency, ensure operator safety, reduce long-term costs, and support the implementation of effective maintenance strategies.

Maintenance Procedures

- Regular Inspections

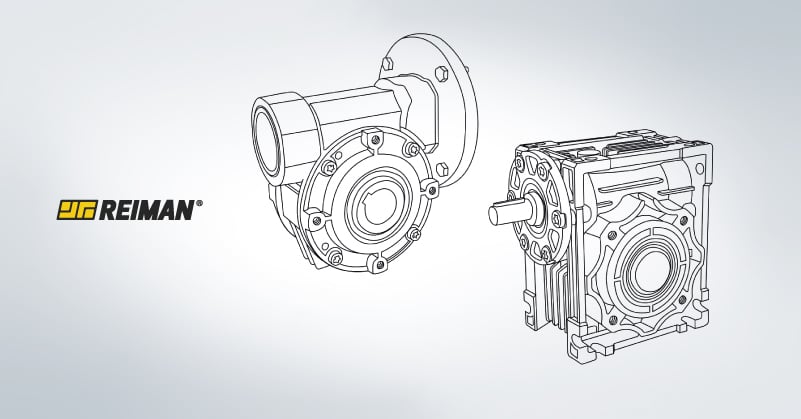

During these inspections, it is important to check for any oil leaks, inspect for abnormal sounds and vibrations, and verify the tightening of bolts and fastenings, as well as detect any potential premature wear of moving components such as shafts, couplings, etc.

These procedures are crucial to ensure that all parts are functioning correctly.

- Proper Lubrication

Proper lubrication is essential for the correct operation of Bernati gearboxes.

Proper lubrication is essential for the correct operation of Bernati gearboxes. Lubrication reduces friction between all the moving components, mainly gears and bearings, thus guaranteeing an adequate operating temperature, greater efficiency and, consequently, a longer service life for the equipment.

Size 025 to 090 gearboxes and pre-reductions are supplied with a high-performance synthetic lubricant. On the other hand, size 110, 130 and 150 gearboxes are supplied with mineral lubricant. It is essential to follow the manufacturer's recommendations regarding the type of lubricant to be used and the frequency of replacement.

All Bernati gearboxes have lubrication points in multiple locations to allow not only easy lubricant replacement, but also the installation of breather plugs.

- Component Check

Regular inspection of internal components, such as bearings and seals, is important to identify signs of wear and prevent premature failure.

Assessing gear wear is also important, as excessive wear can affect the efficiency and operation of the gearbox. Damaged components should be replaced immediately to prevent further damage to the system.

Proper and regular maintenance of worm gearboxes is essential to ensure the efficiency, durability and safety of industrial systems.

Following the manufacturer's recommendations, consulting the catalogue and technical data sheets for the gearboxes, as well as carrying out periodic inspections are indispensable practices for preventing failures, extending the useful life of the components and guaranteeing proper and safe operation of the equipment.