We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Decarbonization in Industry

The industrial sector is one of the largest emitters of greenhouse gases, responsible for 25% of global emissions, according to 2021 data from the International Energy Agency (IEA).

Most traditional industrial processes generally rely on fossil fuels and raw materials, leading to a significant increase in carbon dioxide emissions. Consequently, this contributes to global warming and climate change.

There is a multifaceted approach to industrial decarbonization, and REIMAN's solutions can potentially contribute to various aspects:

- Improving energy efficiency (EE)

Nowadys, energy efficiency is a fundamental requirement across the industry due to its goal of reducing energy consumption and carbon footprint, as well as lowering operational costs.

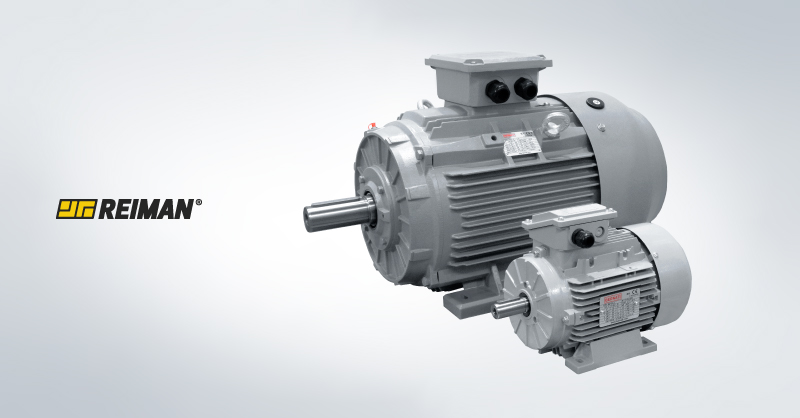

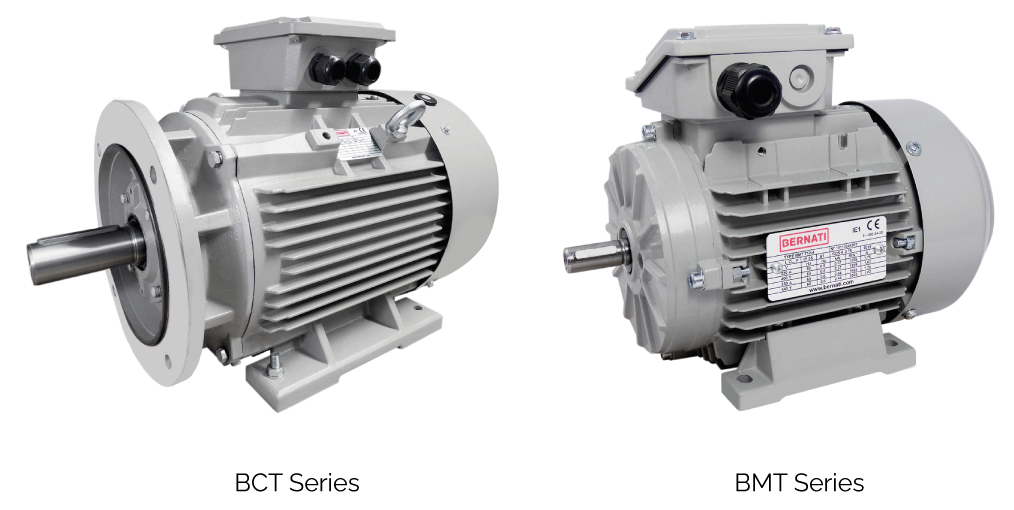

REIMAN offers electric motors with a high energy efficiency rate of up to 97 per cent, which requires less energy to perform the same task as a motor with a lower energy efficiency rate. REIMAN's IE4 electric motors are available in the BCT and BMT series, in various sizes.

Electric motors with high energy efficiency also enable significant savings, in addition to the return on invested capital (ROI).

- Eletrification

As previously mentioned, decarbonization efforts involve transitioning from fossil fuels to more sustainable sources, such as electricity. It's important to note that this energy transition isn't accomplished by simply and suddenly abandoning fossil fuels but rather through a gradual shift.

In addition to electric motors, REIMAN offers variable frequency drives, which are an efficient and cost-effective solution for optimising energy consumption.

In the industry, a variable frequency drive can be used to control the frequency of pumps, fans, compressors, elevators, air conditioning systems, among other equipment. In most applications, with a variable frequency drive it is possible to adjust the motor speed to the ideal speed for the process, allowing for significant energy savings.

- New Technologies

There are several materials that play an important role in decarbonization and the transition to a more sustainable world. Due to its characteristics, aluminum is one of the materials that contributes most to the reduction of greenhouse gas emissions.

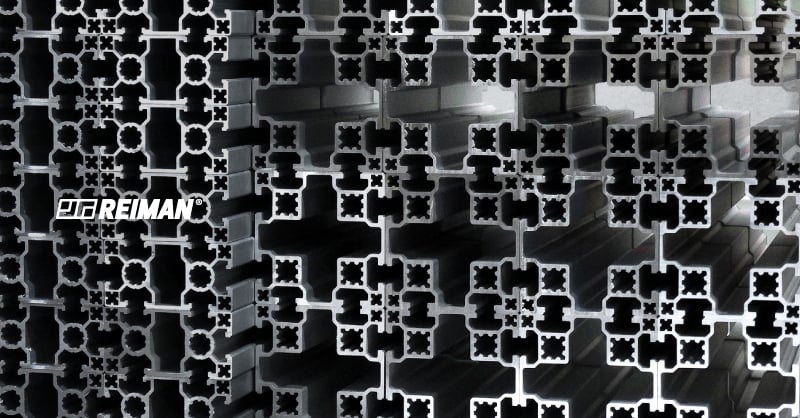

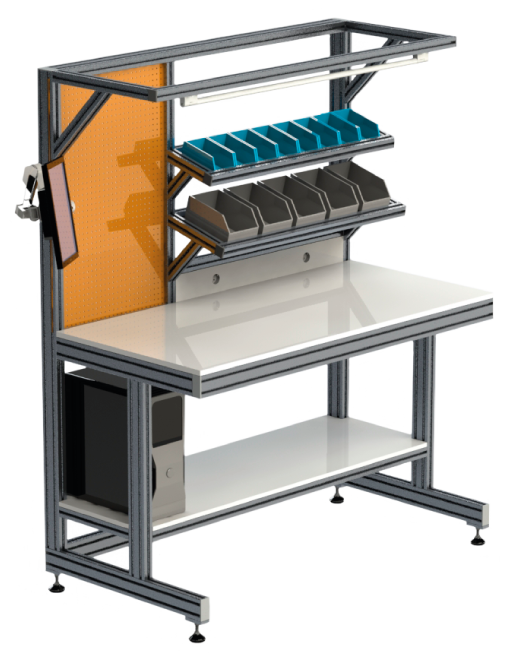

REIMAN not only offers anodised extruded aluminium profiles, available in their original colour and black, with the possibility of anodising in various shades, but also specialises in the development of modular structures. These structures are lightweight and resistant and can be easily removed.

Furthermore, the structures made of extruded aluminium can be easily modified, allowing for great flexibility and adaptability in the project. They can also be easily dismantled, reused or recycled.

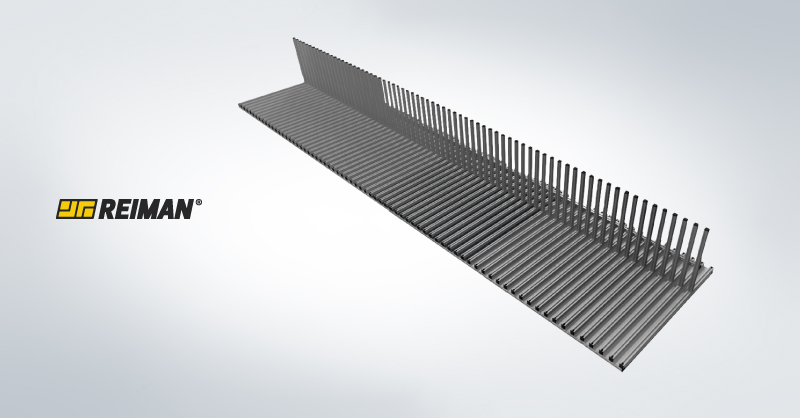

Another sustainable solution is Sealing Profiles, which serve the purpose of sealing against the weather and protecting equipment and people, preventing air leaks and the entry of dust and particles, while maintaining temperature and air quality. They are therefore important in increasing the durability and reliability of various components and systems.

REIMAN provides a wide range of sealing solutions, both standard and custom-cut seals for specific industrial needs. They are developed to meet the highest quality standards, offering reliable and long-lasting protection in various environments.

These seals increase the lifespan of equipment and reduce the need for repairs and replacements, thus reducing resource consumption and waste creation.

REIMAN is committed to sustainability and the decarbonisation of industry, offering its customers solutions capable of reducing carbon and greenhouse gas emissions.