We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Blog

5 Advantages of Anodized Aluminium Profile

As we all know, aluminium profiles are widely used in various industrial sector due to their strength, durability and versatility.

Anodizing an aluminium profile consists of subjecting it to an electrochemical process in which an oxide layer is created on the surface of the aluminium.

The final outcome gives the aluminium profile advantageous properties, which is why every profile REIMAN offers is anodized. ...

Read More »

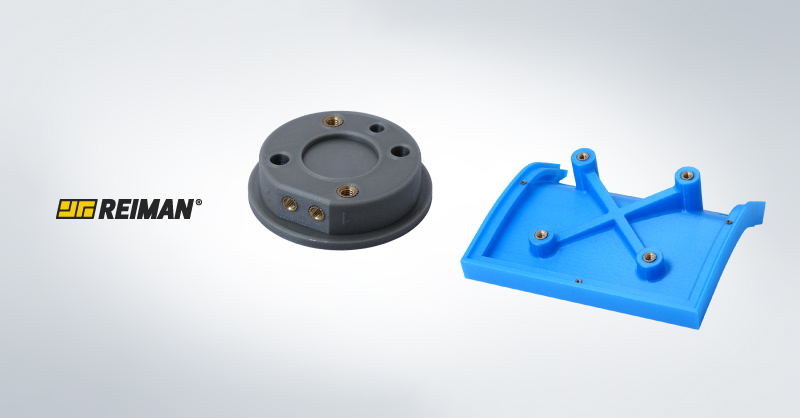

Threaded Inserts in Additive Manufacturing Parts

Threaded inserts are fasteners designed to be used in parts that are not strong enough to support a threaded connection directly. Additive manufacturing parts made of plastic can be produced with a thread included in the structure itself, however, in cases of frequent screwing, the part's thread will wear out, causing cross threading. In this case, designing a part with a purposeful area for installing threaded inserts will always be the safest option. ...

Read More »

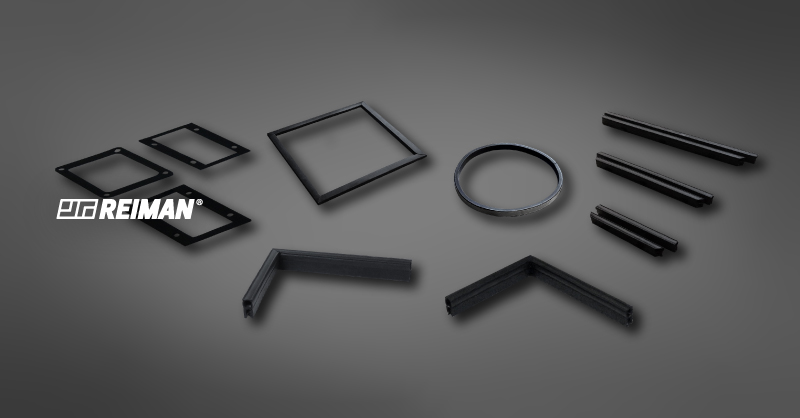

Standard and Custom Industrial Gasket Profiles for Sealing Applications

At REIMAN, we specialize in providing a comprehensive range of gasket solutions, both standard and tailor-made for specific industrial needs. Our gasket profiles are designed to ensure effective sealing in diverse applications, including enclosures, cabinets, vehicle doors, and more.

They are engineered to meet the highest quality standards, offering reliable protection and durability in various environments. ...

Read More »

Customized Gaskets: A Quality Commitment

REIMAN expands its added value services range by presenting a new service based on gasket profile customization. A service capable of providing the most suitable solutions to your most specific needs. ...

Read More »

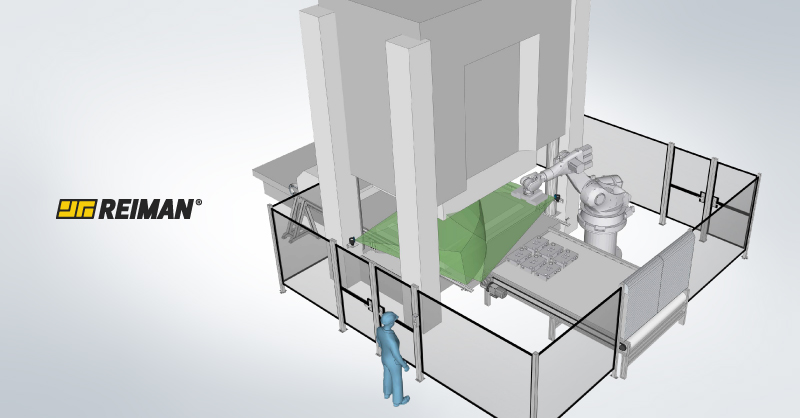

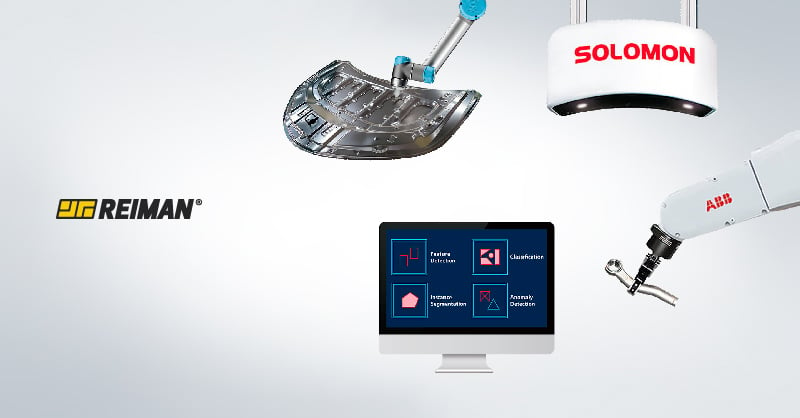

Artificial Intelligence: Future of Industry?

We are currently living through the 4th Industrial Revolution, known as Industry 4.0, a concept that represents the integration of different technologies and disruptive methods, with the aim of promoting the digitalisation of activities and productive processes, improving and increasing their efficiency and productivity.

One of the technologies within this revolution is Artificial Intelligence, which encompasses others such as machine learning, artificial neural networks, computer vision, intelligent robotics, autonomous vehicles, among others. ...

Read More »

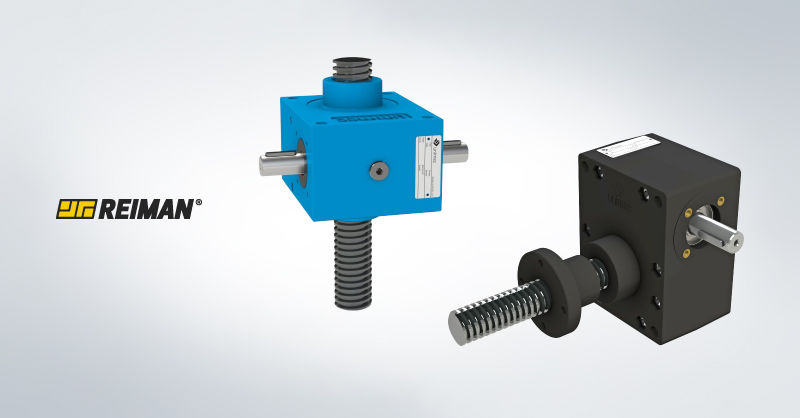

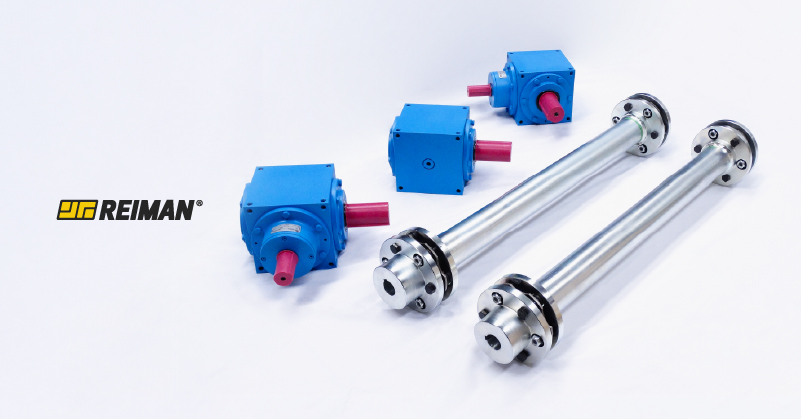

What are Screw Jacks?

Screw Jacks are devices whose function is to convert circular motion into linear motion. This is a mechanism that can be used to move weights with a minimal applied force, by means of a spindle driving the carried weight. Screw jacks' different application approaches envolve carrying weight by pushing or pulling, lifting or lowering, locking or unlocking, sliding, rolling, tilting and tensioning. Whatever type of screw jack is added, the carrying capacities can be used in applications for small weights from just a few kilograms up to hundreds of tons. ...

Read More »

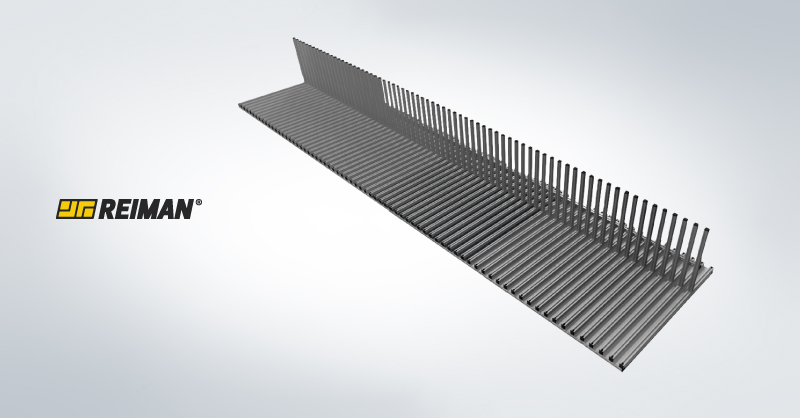

Aluminium Profile in a Automated Storage System

The demand for efficiency and flexibility in automated storage systems is constant, driven by the increasing complexity and dynamics in resource and space optimization.

In this context, REIMAN was driven to develop an aluminium profile structure designed for an automated storage system. ...

Read More »

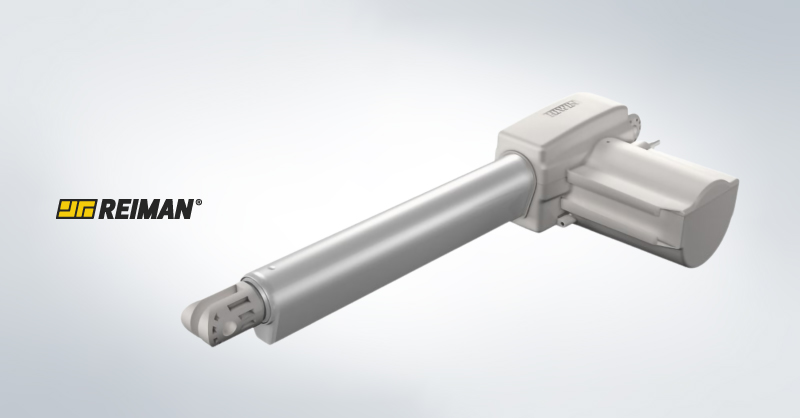

What is a Linear Actuator?

The linear actuator is an electric device that allows movement in one direction, for both ways, through a linear system. A linear actuator’s versatility allows it for pushing and pulling, going up or coming down, inclining, sliding and adjusting the applied object attached to it. A linear actuator grants a lifelong run, with little to no maintenance necessity, and gives the operator full control over how the actuator is used. In comparison to hydraulic or pneumatic systems, a linear actuator is easier to install in an application, as well as less expensive. ...

Read More »

How does 3D printing significantly reduces waste?

Additive manufacturing, popularly known as 3D printing, plays a crucial role in optimizing industrial processes, not only due to its ability to produce complex and independent parts but also because it significantly reduces the waste of raw materials compared to traditional methods like subtractive manufacturing. ...

Read More »

What types of Operating Elements are most commonly used in industry?

Embraced in the generic portfolio of Operating & Machine Parts, Operating Elements are very important, allowing the manual (...) in many industry sectors. Due to its fact, it's necessary to ensure the product in hand to be perfectly adapted and ergonomic for manual use. Elesa+Ganter's handwheels and crank handles are well thought, designed and produced to correspond to its necessitites of any workplace, suiting the material to its composition and the way they must be driven. These are the types of handwheels and crank handles applied in the industry. ...

Read More »